- Home

- Companies

- Ceramix(Luoyang) New Energy Technology ...

- Products

- Ceramix - Prismatic Cells Battery Pack

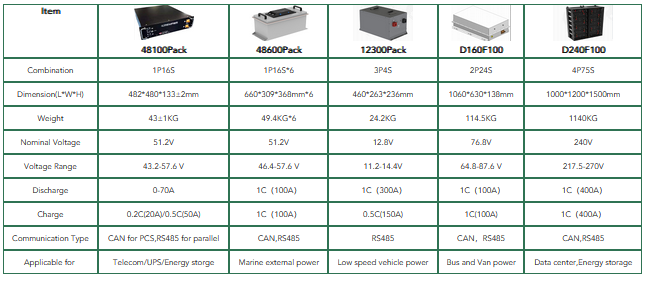

Ceramix - Prismatic Cells Battery Pack

PACK consists of battery module, bus bar, soft connection, protective plate, outer case, output, highland barley paper, plastic support and other auxiliary materials.In most cases, Pack is a lithium battery completed product that can be installed directly or used independently.

- The perfect simulation system of "single cell → module → battery pack"

- Simulation production line and lab.

- Prototype design → simulation → experiment → optimization →... → Design finalize

- High mechanical safety

- High electrical safety

- Best BMS configuration

Prismatic Cell Pack, whose important structural components include: top cover, case, positive plate, negative plate, diaphragm laminated or winding, insulation parts, safety components, etc. Prismatic cell type is mainly made of aluminum case, the structure is relatively simple, unlike cylindrical battery with higher stainless steel case, what’s more the pack with explosion-proof safety valve and other accessories is a safety guarantee, so the overall accessory weight is lighter, higher reliability and higher relative energy density. The prismatic cell pack can be customized according to the size of the product.

- Maximum single cell capacity

- High energy density, large capacity system group technology is simple, good stability

- The consistency of single cell is slightly poor. if the test is not strict enough, which will affect the battery pack life