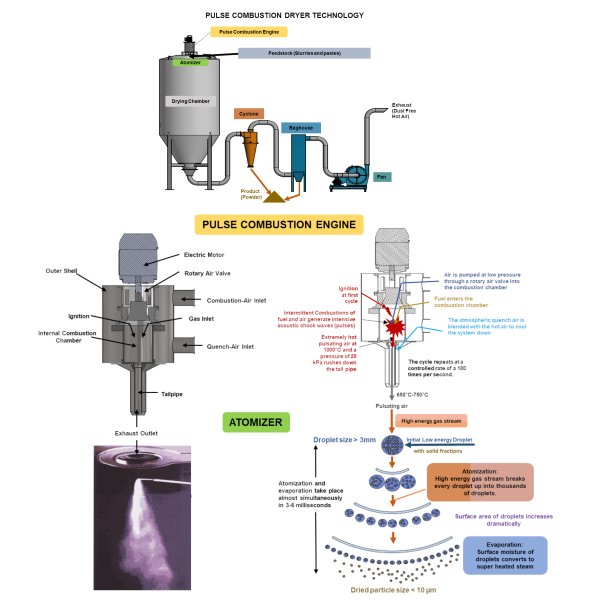

Pulse Combustion Dryer Technology

The term pulse combustion originates from the intermittent (pulse) combustion of gaseous fuel in the pulse combustion engine, in contrast to continuous combustion in conventional burners. Such periodic combustions generate intensive pressure, velocity, and to a certain extent, temperature waves propagating from the pulse combustion unit through a tailpipe (a diffuser) to the process volume of the drying chamber. In order to excite enhanced pulsation in the drying chamber, the operating frequency of the pulse combustor engine must match the frequency of one of the natural acoustic (dynamic) modes of the process volume . When this condition is satisfied, the pulsations are in resonance and the process is resonance-driven.

- energy consumption.

- quality of dried product.

- safety in operation.

- the ability to control the dryer in the event of process upsets.

- the ability to perform optimally even with large changes in throughput.

- ease of control.

- minimal environmental impact due to emissions or combustion of fossil fuels used to provide energy for drying.

Extremely short drying time (30-50 ms)

- The drying time depends on the rates at which heat and moisture are transferred to and from the wet material, respectively. Since pulsation of flue gases tends to increase these rates of heat and mass (moisture) transfer, the application of pulse combustion in drying increases the productivity of such dryers by decreasing the required residence time in a drying chamber and thus allowing for more material to be dried in a given time.

- The higher heat- and mass (moisture) transfer rates cause a larger fraction of input energy to be transferred to the wet particles from flue gases. This translate into lower fuel consumption.

High thermal efficiency

- Sufficient energy is absorbed by the evaporating water allowing very little increase in the temperature of the solids. The extremely short time the solids are exposed to the heat source ensure that the characteristics of the solids are preserved.

- PCD is effective for the drying of all types of materials (Granules, powders, non-cohesive filter cakes, cohesive filter cakes, hard pastes, sludge, high-viscosity pastes and low viscosity pastes). The feed material can have a very high percentage of solids.

Environmentally friendly

- The use of no sulphur-containing fuels such as propane or natural gas and the rapid combustion ensure extremely low nitrogen oxide (NOx) and CO emissions. This is especially advantageous in drying foods and bio-products.

- Small physical plant footprint because no heat exchangers are required. c) Lower air volumes discharged to the admosphere than conventional dryers

Energy Efficient

- Pulse Combustion Dryers require less air than conventional dryers which results in smaller drying chambers and less electrical output for fans. 20-30% lower running costs than spray driers

Low maintenance costs

- No high pressure pumps or high rotating equipment only a low pressure system ensures low maintenance. b) The atomization nozzle is so large — essentially, it’s an open pipe — abrasive and corrosive materials cause little harm.The parts in the atomizing process therefore requires little maintenance.

The pulse combustion engine consists of an outer shell, an internal combustion chamber, a rotary air valve, a gas inlet, a gas pilot, a quench air inlet, a tailpipe and exhaust . The electric motor on top of the outer shell is used to rotate the rotary air valve as required.

For an operation cycle, air is pumped at low pressure into the outer shell and through the rotary air valve into the internal combustion chamber. At the same time, the fuel enters the combustion chamber and is ignited. A small explosion in the combustion chamber follows, creating extremely hot air (1000°C) at around 20 kPa pressure - a pulse or a sonic wave - that moves at high velocity down the tailpipe . The hot air is prevented from flowing upwards from the combustion chamber . Before it reaches the atomizing nozzle at the end of the tailpipe, the quench air is blended with the hot air to cool the air down to 650°C-750°C.

The rotary air valve closes just after ignition and as the combustion chamber empties, the rotary air valve opens again. The next charge of fuel and air enter and when they mix, the temperature of the chamber cause the next ignition. The cycle repeats at a controlled rate of around 100 times per second.

Gas-dynamic atomization takes place at the top of the drying chamber, where a low-pressure, slow-moving viscous feed (slurries and pastes) is introduced through a single pipe into the pulsating very-high-velocity gas stream. The initial droplets are quite large, as the feed introduction nozzle is a straight pipe with no restrictions. As soon as the low-energy droplets experience the high energy of the gas stream, they break up into thousands of droplets through a process of successive division. The surface area of the droplets increases dramatically and efficient evaporation of the surface moisture occurs at up to 98%. Thus, atomization and evaporation happen at exactly the same point in space and time, under extremely turbulent conditions.

In other words, within 3 to 6 milliseconds the pulsating exhaust gases with temperatures of 650°C-750°C produce ultra-fine (5-50μm) droplets and convert the surface moisture of the droplets into super-heated steam, leaving behind a very dry, fine powder with sphere shaped, smooth surfaced particles.

Although the temperature of the gas used to dry the product is very high (650°C-750°C), sufficient energy is absorbed by the evaporating water allowing very little increase in the temperature of the solid particles.