- Home

- Companies

- Naldi Ecologia S.r.l.

- Products

- Quarzite-Carbon Filtration System

Quarzite-Carbon Filtration System

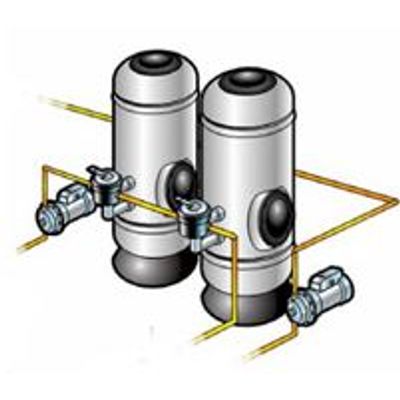

This section has the function of treating the clarification coming from the upstream treatment line through a finishing post-treatment on pressure column filters appropriately sized for the purpose intended. The device operates with pressure columns in standard manual or automatic request and the purpose of the phase is the removal of extremely fine suspended material not to be sedimented in times compatible with the upstream process (quartzite filters), and / or to remove organic or non-biodegradable organic substances that may be present in the sewage (GAC granular activated carbon filters).

The amount of adsorption depends on various factors including:

- sup. specific of the absorbent - nature and concentration of the adsorbate polarity

- temperature

- adsorption kinetics as a function of the plurality of the adsorbates

If a minimum contact time is not guaranteed due to the high hydraulic loading speed, the amplitude or better length of the adsorption zone will be greater than the expected bed and the pollutants will not be adsorbed.

The adsorption phenomenon consists in the diffusion process of organic molecules crossing the pores of the GAC. The columns adopted are fixed-bed in equicurrent, so that both absorption and filtration of the SS is carried out until it is packed.

This entails frequent or systematic washing for the removal of retained suspended substances. The periodicity of the washing phase as well as the eventual yet remote replacement of the porous masses (quartzite / carbons) depends on the working conditions and the experience gained over time for which there is not a pre-established rule (it is a good rule however to provide every three or four days to a washing operation lasting about 15 minutes). The station is however equipped with an analogue pressure switch on which a graduated scale is shown that detects the working range within which to operate the filtration cycles (generally 0.5 ÷ 1.5).

Phenomena of exceeding this range are indicative of a condition of clogging of the filtering columns and of the need to intensify the washing phases up to possible total renewal of the masses. On the occasion, the station provides a hydraulic kinematics capable of managing the filtration water during the maintenance of the filters by-passing the columns and temporarily sending the water directly to the drain.

The treated waters are then collected in a containment tank downstream and, in the presence of a loading device, they are re-launched in final discharge after passing through a fiscal well.

The line in its manual version is managed, controlled and protected by a dedicated QE that, on request, can avail itself of an electronic control unit that manages all the work phases completely independently of the operator`s presence, which in such cases performs the sole and unique supervisory function, including the extraordinary maintenance activities, if necessary.