FCT Systeme GmbH

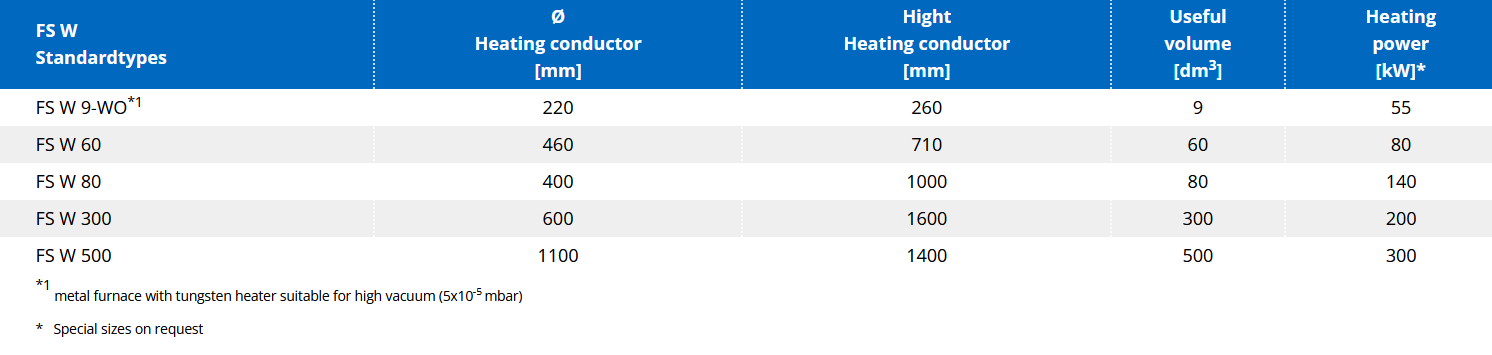

FCT - Model Type FS W -Resistance Heated High-Temperature Vacuum Sintering Furnace

FromFCT Systeme GmbH

These vertical, resistance-heated sintering systems are used in many areas of application, as they can be operated both in a vacuum and in an inert atmosphere. The main area of application is the debinding and subsequent sintering of ceramics, composite materials or powder metallurgical components. They are used in particular for high-temperature processes such as carbonization, recrystallization, silicon infiltration, nitriding (formation of Si3N4), vacuum sintering or metallization. Optionally, these systems can be equipped with a debinding/dewaxing system as a combined process. Rapid cooling is also available to significantly reduce cooling times.

Most popular related searches

high-temperature sintering furnace

sintering furnace

high temperature furnace

furnace

silicon nitride

gas main

carbonization

wall heating

heating and cooling

- sintering in vacuum, partial pressure, relative pressure

- Debinding and/or dewaxing as a combined process

- High flexibility in process optimization and design

- Extensive data evaluation

- Prototype production, series production

- Design: vertical as bottom loader or top loader

- Temperature measurement using a pyrometer

- Working temperature up to 2200°C

- Vacuum: 5x10-² mbar(a)

- Furnace atmosphere: Ar / N2 / forming gases

- Easy accessibility

- Resistance heating

- Double-walled, water-cooled vacuum vessel

- Comprehensive, user-friendly Siemens S7 and WinCC control system

- Working temperature up to 2400°C

- Various gas mixtures can be regulated

- Debinding / dewaxing

- Rapid cooling with internal gas circulation