- Home

- Companies

- Rongsheng Group

- Products

- Rongsheng - Model RSGLJ - High Alumina ...

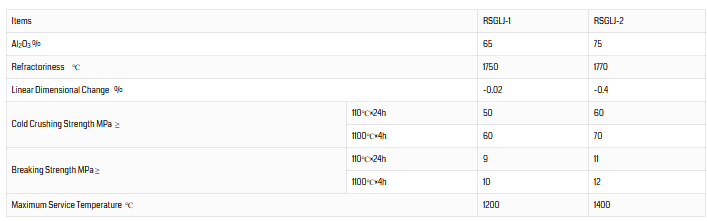

Rongsheng - Model RSGLJ -High Alumina Refractory Castable

High-alumina castable is an amorphous refractory material composed of bauxite clinker (aggregate), binder, and admixture. It can be used directly after adding water and stirring and is formed by vibration casting. High-aluminum castables need a certain amount of time for setting and hardening after construction, so they need to be cured for a certain period before they can be de-molded after casting.

- Product: Refractory Castable

- Function: High-temperature resistance

- Advantages: Convenient construction, wear resistance, corrosion resistance

- Location: Henan, China

- Ready stock: 7-12 days’

- Factory: Established for 20 years, exporting to 80+ countries

- Samples: Samples are available

- Size: Customized

- Service: One-to-one customized refractory products

- Product range: refractory bricks, thermal insulation materials, unshaped raw materials, metallurgical materials

- Reply within two hours!

- Price concessions, quality assurance!

How high alumina castable is produced?

High-alumina castables are based on traditional ingredients, reducing the amount of cement and adding different admixtures, thereby improving product performance, increasing temperature strength and load softening temperature, reducing thermal conductivity, and allowing high-alumina casting. The thermal stability of the material is better.

- Anti-penetration

- Corrosion resistance

- Shock resistance

- Anti-wear

- Good mechanical properties

- Furnace structure integrity is strong

- Excellent air tightness

- Extend the life of the kiln

- Saving furnace maintenance costs

High alumina refractory castables are suitable for kilns, blast furnaces hot blast stoves, heating furnaces, boilers, and cement kilns.