- Home

- Companies

- Shandong Huiyao Laser Technology Co., ...

- Products

- Huiyao - Semi-Automatic Production Line ...

Huiyao - Semi-Automatic Production Line Ev Battery Module

The semi-automatic production line of energy storage battery modules is used in photovoltaic energy storage, solar energy storage, wind energy storage and other enterprises.

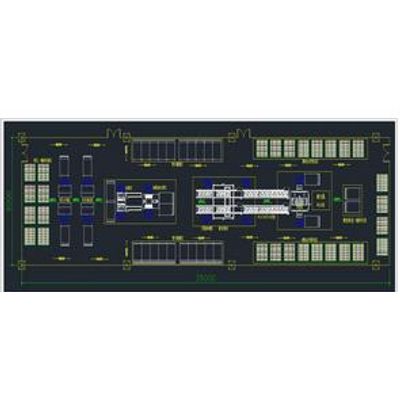

The module line is a semi-automatic battery module line, which adopts a parallel design of left and right double stations; the main functional process is divided into three processes: battery incoming processing, battery stacking processing, and battery pole welding processing.

The battery cell sorting and cleaning station is a manual operation station; the function of this station is to perform battery cell sorting and scanning after receiving the battery, and put it into the transfer cart after cleaning, and then transfer to the next station.

Dispenser configuration:

X-axis stepper motor drive, stroke 500mm, Y-axis stepper motor drive, stroke 300mm, Z-axis stepper motor drive belt, stroke 300mm, motion accuracy ±0.02mm; the host and industrial computer are integrated in the workbench.

Conveyor belt configuration:

With speed control function, detection stop function.

Extrusion tooling:

With pressure detection and size detection functions.

Circulation car:

Used for circulation and temporary storage of battery modules.

Operation process: The operator puts the sorted batteries and end plates on the dispenser fixture in turn for dispensing, and then puts them on the assembly line; the operator places the glued batteries on the stack according to the module arrangement requirements On the extrusion tooling, after the placement is completed, squeeze, cover the steel belt, and hit the packing belt; take the packaged module out of the stacking extrusion tooling, place it in the circulation trolley, and send it to the module static area.

The pre-welding inspection and pole cleaning position are semi-automatic stations. After manually putting the module into the cleaning transmission line, after checking whether the module is normal, start the cleaning button, and the transmission line will send the module to the cleaning station for cleaning (the cleaning mechanism is mobile Type cleaning, the plasma cleaning head is fixed, the module will clean the pole after the module passes through the assembly line), the module will flow into the BUSBRA installation position after cleaning, which is the BUSBRA installation.

Welding station configuration:

X-axis servo motor drive, stroke 1000mm, Y-axis servo motor drive, stroke 600mm, Z-axis servo drive with brake, stroke 400, motion accuracy ±0.01mm; the host and industrial computer are integrated in the workbench.

Operation process: manually put the cleaned battery module into the welding fixture, confirm that the welding position has no obvious deviation, push the fixture into the welding position, press the welding button to weld, after completion, pull out the fixture, take out the module and place it on the right Side flow and get off the car, send it to the follow-up inspection and auxiliary material installation process;

The welding station is a left and right double station welding station, which can be used interactively, with left station loading, right station welding, right station loading, and left station welding, realizing uninterrupted welding and improving equipment utilization.

- Applicable module size range 250-516mm

- The extrusion pressure can meet 4000N,

- Adopting a speed-regulating motor, the screw feed speed is 35-122.5mm/min, the actual feed distance required for extrusion is 20mm, and the feed time is 10-34S.

Operation instructions:

Push the stacking fixture to the stacking position (Figure 2), put down the rotary plunger, and fix the stacking fixture; put the glued cells into the stacking fixture limit slot in order of groups and arrange them neatly. Use your hands to moderately squeeze, place the glued end plate, moderately squeeze, and complete the stack; pull up the rotary plunger, push the stacking fixture to the squeezing position (Figure 2 Station 1 state), and lower the rotary plunger , Fix the stacking fixture; rotate the corresponding squeeze start switch to squeeze. When the limit piece touches the front limit switch to reach the set size, the motor stops (if the set size is not reached, the squeeze pressure reaches the set value first 4000N, the motor stops rotating, the pressure display interface shows that the current pressure module size is unqualified, adjust the battery cell combination); reach the set size, put on the steel belt, rotate the corresponding pressure relief start switch, and make the hand wheel rotate one circle Turn off the pressure relief switch (one turn of the handwheel here is the length reference unit, assuming the value, the length is actually determined according to the process conditions) to force the steel belt; use a baler to bind the plastic steel belt; rotate the corresponding pressure relief start switch, when After the limit piece touches, the limit switch reaches the far point, and the motor stops; pull up the rotating plunger, push the stacking fixture to the stacking position (Figure 2 station two state), put down the rotating plunger, fix the stacking fixture; take out the electricity The core module is placed in the static zone for standing, completing the entire stacking, squeezing and bundling process.

Switch module operation:

loosen the top wire on the sliding nut to make it rotate on the screw rod, rotate the pneumatic switch to make the pointer reach the set size position, and at the same time, the sliding nut needs to be twisted to reach the set position, just right Trigger the front limit switch, measure whether the distance between the two extruded end plates is the same as the set value, lock the sliding nut, and complete the module switching operation.