- Home

- Companies

- Elcogen AS

- Products

- Solid Oxide Electrolysis Cells

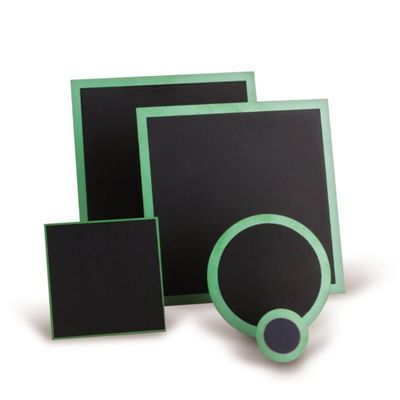

Solid Oxide Electrolysis Cells

We provide mass manufactured planar, Solid Oxide electrode-supported Cells (SOC) operating at 600-800 °C. Elcogen cells are the market’s most efficient solid oxide technology, suitable for electrolysis (SOEC), co-electrolysis (co-SOEC) and reversible (rSOC) operation modes. Cells can be incorporated into third party stacks for commercial applications, including heat and power generation, green hydrogen production, renewable energy storage, industrial process gas, and production of synthetic fuels and chemicals. The low cell operating temperature enables longer lifetimes and the use of low cost materials at stack and system level.

| Technical data | ASC-300C | ASC-400B |

| Fuel contact layer | NiO | NiO |

| Fuel electrode support composition | NiO/YSZ | NiO/YSZ |

| Fuel electrode functional composition | NiO/YSZ | NiO/YSZ |

| Electrolyte composition | YSZ | YSZ |

| Electrolyte thickness | 3 or 6 μm | 3 or 6 μm |

| Half-cell thickness | 300 μm | 400 μm |

| Half-cell tolerance | ±30 μm | ±40 μm |

| Barrier composition | GDC | GDC |

| Oxygen electrode composition | LSC | LSC |

| Thickness of oxygen electrode | 15 μm | 15 μm |

| Total thickness | 315 μm | 415 μm |

| Thickness tolerance | ±35 μm | ±45 μm |

| Suggested operating temp | 600–800 °C | 600–800 °C |

| Standard size (cell) | 12x12 cm | 12x12 cm |

| Standard size of active area | 11x11 cm | 11x11 cm |

| Different sizes available | + | + |

| Different shapes available | + | + |

| Half-cells available | + | + |

| Contact layer of Oxygen electrode available | + | + |

Elcogen provides technical support to all of its Solid Oxide Cell customers.

- Cell integration support to third party stacks

- Customised cell testing

- Customised cell manufacturing

- Analysis of results before and after testing

- Assistance in operational protocol development based on customer requirements

- Research and engineering assistance related to cells

Quality assurance of solid oxide cells

Elcogen’s cells meet the highest quality standard on the market. Elcogen’s cell technology development and cell production are certified and meets ISO 9001:2015; ISO 14001:2015 and ISO 45001:2018 management standard. We have developed an internal multi-step cell quality assurance procedure that enables us to trace each cell throughout the production process from its origin on material level to ready-to-ship product.

Production capacity

Starting from 2024 Elcogen’s cell production capacity target is around one million cells per year and increasing every year. Starting from 2030 our target is provide GW-scale production capacity of solid oxide fuel and electrolysis cells. Our flexible cell production capability enables us to produce small quantities of cells for validation, testing and demo projects and larger volumes needed for commercial projects.

Ready for commercialisation

Elcogen’s SOEC cells are mass manufactured and ready for commercialisation. Cells can be incorporated into third party stacks for commercial applications. We currently supply more than 40 commercial customers globally.