Henan SRON SILO ENGINEERING Co., Ltd.

- Home

- Companies

- Henan SRON SILO ENGINEERING Co., Ltd.

- Products

- SRON - Wood Pellet Steel Silos for ...

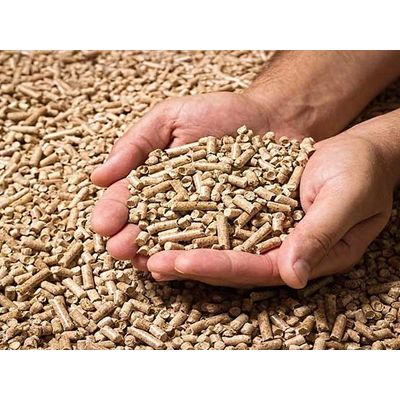

SRON - Wood Pellet Steel Silos for Storage

SRON provides advanced storage solutions for wood pellets, sawdust pellets, and feed pellets with their high-quality steel silos. These silos come in two types: galvanized corrugated steel and spiral steel. Both types are known for their excellent corrosion resistance, sealing performance, and durability. The galvanized corrugated steel silos are lightweight, high-strength, and easy to assemble, making them suitable for large-scale wood pellet storage. The spiral steel silos are made by spiraling a steel plate, offering superior structural strength and bonding quality. The maintenance cost of these silos is low, and they generally have a service life of up to 30 years. These silos are suitable for applications in biomass power plants, livestock, and poultry breeding industries. Added auxiliary systems like drying, temperature measuring, and automatic controlling enhance functionality. Key technical factors include capacity planning, thermal insulation for moisture control, and robust extraction systems for efficient discharge, contributing to reliable and safe storage solutions.Most popular related searches

wood pellet silo

wood pellet storage

wood pelletizing

wood pellet

wood pelletting

wood pellet storage silo

biomass-powered plant

biomass power plant

sawdust wood pellet

thermal insulation

Storage Materials: Wood Pellet, Sawdust Pellets, Feed Pellets, etc.

Storage Capacity: 100ton-15000ton

Silo Type: Galvanized Corrugated Steel Silo, Spiral Steel Silo

Application: Biomass Power Plant, Livestock and Poultry Breeding Industry, etc.

Silo Bottom Type: Flat Bottom, Hopper Bottom

Auxiliary System: Conveying System, Drying System, Temperature Measuring System, Ventilation System, Automatic Controlling System and Other Supporting Systems.

As a silo manufacturing project company, SRON provides customized and EPC solution services according to different functional needs, site and climate conditions and investment plans of each client's project.

Steel silos are widely used in the storage of wood pellet, sawdust pellet. The steel plates used in producing this kind of steel silo have excellent corrosion resistance and sealing performance, which makes steel silo durable and has good moisture-proof and waterproof performance, which is very suitable for large-scale wood pellet storage.

SRON has over decade years’ experience in the designing, manufacturing, installation and maintenance of steel silo, used for store wood pellet, sawdust, maize, wheat, etc. Our wood pellet steel silo is known for its light weight, easy maintenance, and solid structure, and can be customized designed in various sizes for clients’ needs.

Wood pellet storage typically employs either galvanized corrugated steel silos or spiral steel silos (commonly known as Lipp silos). Below, I'll provide an introduction to the characteristics of the 2 types steel silo:

Galvanized Corrugated Steel Silo for Wood Pellet:

The galvanized corrugated steel silo is an advanced storage structure manufactured using highly corrosion-resistant galvanized corrugated sheets. It is characterized by being lightweight, high-strength, and easy to assemble. Its unique design ensures a robust structure and durability. Additionally, it can be equipped with insulation layers based on specific needs, making it particularly suitable for the safe storage of wood pellet particles.

Advantages:

1. On-site Installation

Wood pellet galvanized corrugated steel silos can be assembled directly on site, with fast construction speed and low professional and technical requirements for installers;

2. Thermal Insulation Air-tight Treatment

This silo type can be configured with an insulation layer to create an airtight insulation silo. Because of the flammability of wood pellets as a raw material for energy combustion, if they are stored in silos for a long time in areas with high temperatures, you can consider equipping them with an insulation layer for safety reasons.

3. Low Cost

Compared with concrete silos, steel silos are light in weight and have low requirements on the foundation, so they consume less steel and reduce the basic cost.

4. High Degree of Standardization

SRON bolted steel silo has a high degree of standardization. According to domestic materials, standardization, generalization and serial production can be adopted, and standard parts can be produced and installed on site.

5. Short Construction Period

The assembly of galvanized corrugated assembled steel silos is simple and fast, and all its parts are connected by bolts, thus shortening the construction period.

6. Long Service Life

The maintenance cost of the galvanized corrugated assembled steel silos is low, and the service life is suitable, which can generally reach about 30 years.

Spiral Steel Silo for Wood Pellet

Spiral steel silo also known as Lipp steel silo which is made by spiraling the steel plate with a certain width into the rolling equipment during construction.

The protruding undercut thickness of the spiral silo is 5 times of the original steel plate thickness, which strengthens the structure and the bearing capacity of the silo. The structure of the silo body is integrated without any holes, bolts and screws, so it has good air tightness. In addition, the use of galvanized steel make the silo reach a good corrosion resistance & long service life.

Advantages

1. High strength: the inner wall of the silo has vertical reinforcing ribs and transverse spiral undercut ribs, which greatly enhances the strength of the silo and has strong wind, earthquake and snow load resistance;

2. Good sealing performance: the cylinder of the silo is connected by spiral undercut, with excellent sealing performance;

3. Short construction period: silo could be put into use as soon as possible to create benefits for users;

4. Long service life: the cylinder of the silo is made of hot-dip galvanized coil, and the top of the silo is treated by galvanizing process, with strong corrosion resistance and long service life;

5. Space saving: the distance between the two silos can be as low as 500mm, which can make full use of the space and reduce the floor area.

6. Light weight: the silo has low weight, which greatly reduces the load and cost of the foundation structure.