- Home

- Companies

- MK Magnetics, Inc.

- Products

- Standard & Custom Tape Wound Soft ...

Standard & Custom Tape Wound Soft Magnetic Cores

As an industry leader in the design and manufacturing of tape wound soft magnetic cores, at MK Magnetics, Inc. we are in a unique position to identify industry trends and changing customer needs. Early on in our history, we recognized a deficiency within the industry for custom manufactured tape wound soft magnetic cores. Although our lines of standard products are extensive, the increasing shift towards custom designs was an area of that required a solution. To accomplish this, MK Magnetics assembled a team of highly experienced tape wound core veterans with the goal of augmenting standard cores with highly customizable products. Superior Engineering and Customer Service Support are an inherent part of this process which allows MK Magnetics to manufacture cores that provide maximum performance.

From innovative engineering to cutting edge materials such as nanocrystalline, various amorphous materials, 3% grain-oriented and 6.5% non-oriented silicon steel, 50% and 80% nickel materials, Supermendur, and many other highly specialized materials.

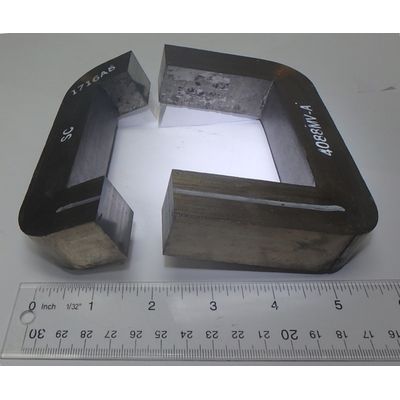

Another key advantage of this service is the flexibility of MK Magnetics manufacturing capabilities. Within our facility, we can build cores weighing from .002 up to 4,000 lbs. +, and in dimensions up to 7.5’ in height by 4’ in width, depending on overall geometry. They can be configured as C, E, and pie type D-cores, cased and uncased toroid, bars, and a variety of custom shapes. We also have the flexibility and expertise to develop custom processes to accommodate virtually any core design with no restriction on volume. This is comprehensive offering and is backed up by a robust quality program and a full range of in-house testing capabilities, providing compliance with various industrial standards. MK can typically begin delivering in 3-5 weeks with expedited deliveries available.

Generally made from thin strips of soft magnetic materials, cores are available in various shapes, weights, and material thicknesses to suit different frequency, flux densities, and other requirements. The MK Magnetics team will work with you to meet your specifications by combining innovative engineering with access to cutting-edge materials typically used in the manufacture of tape wound cores. These materials may include:

- Nanocrystalline materials: These polycrystalline materials are made from crystallites that are a few nanometers in size (typically less than 100 nm). Cores made from them generally offer high permeability and saturation and very low power loss.

- Amorphous metals: Amorphous metals have a disordered atomic microstructure. It is non-crystalline and glass-like. Cores made from them have excellent magnetic properties, including high permeability, high saturation magnetic flux density, and low power loss.

- 3% grain-oriented and 6.5% non-oriented silicon steel: Silicon steels are available in two forms: grain-oriented and non-oriented. Grain-oriented silicon steels have magnetic properties developed in the rolling direction, while non-oriented silicon steels have magnetic properties that are similar in all directions. High saturation magnetic flux density and low cost combine to make this a good choice in many applications.

- 50% and 80% nickel alloys: These alloys offer some of the best soft magnetic properties, making them well-suited for use in amplifiers, inductors, transformers, and other magnetics-based devices.

- Supermendur®: This cobalt-iron material has high flux density and low core loss, making it suitable for use in chokes and transformers when size and mass are important, such as in the aerospace industry.

- & many other highly specialized materials!

Another key advantage of working with us is our flexible manufacturing capabilities. We can build cores that are between 0.002 to 4,000 lbs. in weight and up to 7.5 ft. (height) by 4 ft. (width) in size, depending on overall geometry. They can be configured as C-, E-, D-cores, pie-type, cased and uncased toroid, bars, and a variety of custom shapes. We also have the freedom and expertise to develop custom processes to accommodate virtually any core design with no restriction on volume. This is a comprehensive offering and is backed up by a robust quality program and a full range of in-house testing capabilities, ensuring compliance with various industrial standards. Our team can typically begin delivering in three to five weeks. Expedited deliveries are available.

We can design and manufacture a broad selection of standard and custom soft magnetic core products.

Magnetic cores are components made from magnetic materials that are designed to contain and control magnetic fields in electrical, electromechanical, and magnetic devices. We make the following types of cores: tape wound cores, cut C-cores (single-phase), cut E-cores (three-phase), toroids, multiple cut cores, epoxy-coated cores, and Optifficient cores.

Toroids are magnetic cores with a toroidal shape (i.e., a circular ring). This unique shape allows for shorter coils, lower resistive or windings losses, and better overall efficiency in electrical and electronic circuitry assemblies. We offer them in cased, uncased, gapped, and other variations.

In addition to supplying magnetic core components, we also manufacture stacked and custom assemblies.