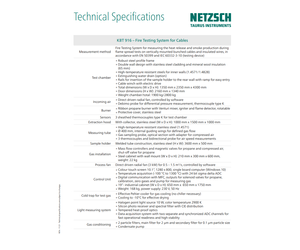

Taurus - Model KBT -Fire Testing System for Cables

Fire testing system for measuring the heat release and smoke production during the flame spread test of vertically mounted bunched cables and insulated wires according to EN 50399 and IEC 60332-3.

Fire Testing System for measuring the heat release and smoke production during flame spread tests on vertically mounted bunched cables and insulated wires, in accordance with EN 50399 and IEC 60332-3-10 (testing device)

The KBT 916 from NETZSCH TAURUS Instruments GmbH is easy to operate, offering innovative control and data acquisition options in an intuitive format with ample user guidance.

The high-resolution color touch display on the “KBT Control” cabinet allows for measuring and control with the integrated Single Board Computer, Windows operating system and KBT software. There is thus no longer any need for manual controls such as switches, controllers or buttons; the status of the testing system is clearly displayed and the system prevents any critical operating errors. The storage, analysis and recording of all test data is handled entirely via the control unit. Well thought-out details along with the use of high-quality materials guarantee the KBT 916 test system a long product life and a low degree of wear and tear.

Features at a Glance

- KBT test chamber with sample holder, hood, collector, measuring tube, gas installation, burner, air supply and sensors

- Double-walled test chamber, stainless steel with mineral wool insulation, opening for air supply at the bottom, opening for smoke extraction, rail guides on the back wall for easy mounting of sample holders, electric winch assembly, stainless steel door with fire-resistant glazing

- Cable winch with electric drive, ramp and option for easier transport of the sample holder

- Exhaust gas fan with flow control for constant exhaust gas flow

- Modules for data acquisition and control of all processes

- Extensive options and accessories for enhancing the exhaust system and for calibrating the KBT test unit

- Stainless steel extraction hood and collector for protection against aggressive gases

- Measuring duct section with bidirectional probe, NiCrNi thermocouples, light measurement system and gas sampling probe

- Ribbon propane burner with venturi mixer, piezoelectric igniter, flame detector, folding mechanism and stainless steel protective cover

- Gas installation with digital gas flow controller, pressure controller and magnet valves

- Supply air process fan with frequency converter and digital control module

- Exhaust air process fan with frequency converter and digital control module

- "KBT Control" measuring and control unit with SBC, 32-GB SSD, Windows 10, 10.1“ color touch screen, SIEMENS gas analyzer, measuring gas processing, measuring and control modules and RS232/USB interfaces

- 19“ PC rack, monitor, printer, PC (option)

- Single license for the KBT software

Analyzer

- SIEMENS ULTRAMAT/OXYMAT 6E

- Measuring components O2, CO2, optional CO

- Automatic calibration of the gas analyzer by software

- Full integration into the SBC system and operation via KBT touch panel

Operating unit KBT

- Windows Desktop PC, 23“ LCD monitor, HP LaserJet

- 19” PC - industrial cabinet with safety glass (W x D x H): 800 mm x 800 mm x

1800 mm, weight: 110 kg; power supply: 230 V, 50 Hz

Software

- Graphical and numerical display of all test results

- User guidance for test procedure

- Easy operation and full gas analyzer control by digital interfaces

- Calibration of test device according to standard (stability, step calibration test,

heptane calibration, light measurement) - Report generator

- Via 10” touch screen of embedded SBC: Control of all hardware components

such as fans, valves, gas analyzer, light measurement system, sensors for

differential pressure and mass flow controller

Calibration gases*

(gases for calibration of SIEMENS gas analysis)

- Synthetic air

- Composition: 20.0 % O2, 80% N2

- Content: 1 bottle (10 l) or more

- Bottle connection: R ¾“ (DIN 477 Nr.9)

- Pressure reducer: display 0-200 bar, control range 0.2-4bar

- Zerogas

- Composition: 100% N2

- Content: 1 bottle (10 l)

- Bottle connection: W 24,32 x 1/14 (DIN 477 Nr.10)

- Pressure reducer: display 0-200 bar, contol range 0.05-1 bar

- Calibration gas

- Composition: 20% O2, 5% CO2, and N2

- Content: 1 bottle (10 l)

- Bottle connection: M19 x 1.5 (DIN 477 Nr.14)

- Pressure reducer: display 0-200 bar, control range 0.05-1bar

Burning gas*

- Bottle size: 50l

- Pressure: ca. 7-10 bar

- Content Propane, commercially available

- Purity at least 95%

- Pressure reducer: 2-4 bar

- Operating pressure: 2-2.7 bar overpressure

Compressed air*

- Application: cleaning the optical components of the light measuring section

- Requirements: oil-free

- Line pressure: 5-8 bar

* Gas to be provided by the user