- Home

- Companies

- Tmeic Corporation

- Products

- Tmeic - Rolling Mills

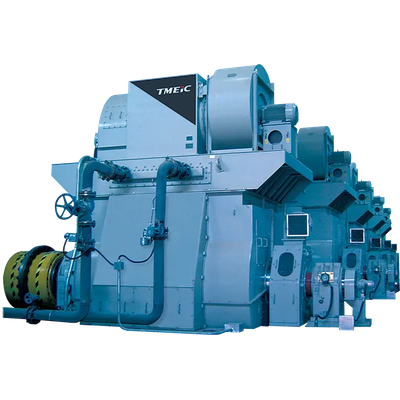

Tmeic - Rolling Mills

AC adjustable speed motor drive systems are the preferred technology for new rolling mill installations and modernization projects.

TMEIC provides advanced AC adjustable speed motor drive systems tailored for both new rolling mill installations and modernization projects. Two motor types meet the range of rolling mill demands: salient pole synchronous motors deliver high torque and power for roughing and finishing stands with excellent control and efficiency, while squirrel cage rotor motors serve medium power needs like reels and auxiliary stands with rugged construction and precise low-speed torque. Both motor types are engineered for superior efficiency, reduced maintenance, and reliable performance under extreme rolling conditions.

Design Feature

- High strength coil head bracing and connections will withstand magnetic forces under frequent reversing direction of rotation.

- On squirrel cage motors, an optimal brazing between rotor bars and end rings will permit the motor to withstand the repeated acceleration, deceleration and reversal of rotation that is typical in this steel processing.

- Detailed analysis of the electromagnetic field patterns and ventilating airflows yields an optimized motor design with maximum cooling and efficiency.

- Application of TMEIC vacuum pressure insulation (VPI) system and very large autoclave can process any size of stator.

- Static and dynamic strength analysis of stator, frame, rotor, shaft and bearings.

- Selection of appropriate forged steel shaft with high tensile strength.

Design Feature

- High strength coil head bracing and connections will withstand magnetic forces under frequent reversing direction of rotation.

- On squirrel cage motors, an optimal brazing between rotor bars and end rings will permit the motor to withstand the repeated acceleration, deceleration and reversal of rotation that is typical in this steel processing.

- Detailed analysis of the electromagnetic field patterns and ventilating airflows yields an optimized motor design with maximum cooling and efficiency.

- Application of TMEIC vacuum pressure insulation (VPI) system and very large autoclave can process any size of stator.

- Static and dynamic strength analysis of stator, frame, rotor, shaft and bearings.

- Selection of appropriate forged steel shaft with high tensile strength.

Salient Pole Synchronous Motors

- Ideal for hot strip mills, roughing and finishing stands

- Excellent torque and superior efficiency

- Unit power factor and easy controllability

Squirrel Cage Rotor Motors

- Designed for reels and medium-power stands

- Strong performance at ultra-low speeds

- Constant power across the weakening range

- Built to NEMA MG1 and JEM 1157 standards

Shared Benefits

- High efficiency and rugged design

- Minimal maintenance requirements

- Fast, responsive control

- Exceptional acceleration and deceleration

- Flexible performance in harsh environments