Trumonytechs - Thermal Conductive Pads

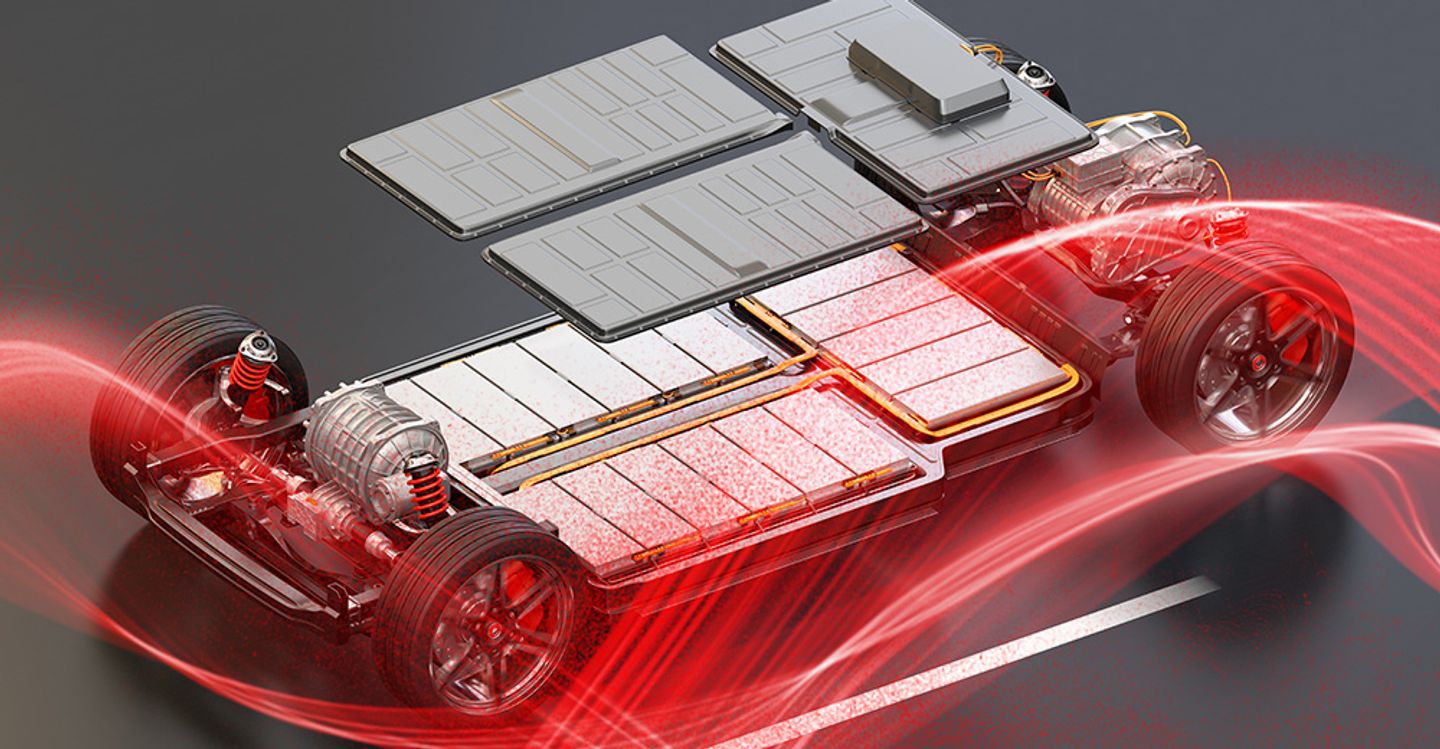

Thermal conductive pads are mainly used to be installed between heat generating electronic components and heat sinks to provide an effective thermal interface environment. It improves the efficiency of heat dissipation between them. Within the thermal interface material industry, silicone thermal pad, also known as thermal conductive silicone film, soft thermal conductive pad, etc., is specifically produced using a gap transfer heat design solution that can fill the gap and complete the heat transfer between the heat generating part and the heat dissipating part.

It is a soft and comfortable pad, which is a kind of thermal conductive medium material synthesized by a special process using silicone as the base material and adding various auxiliary materials such as metal oxides. It is commonly used to install on electronic components to achieve the purpose of thermal conductivity, but also can effectively enhance the overall damping performance, so as to achieve good protection performance for electronic components.

Trumonytechs thermal conductive pads are simple to use and can easily be used in a variety of applications with ease. We offer high volume custom manufacturing for different sizes, thicknesses, and application requirements. Of course, if you have any customization needs, you can talk to our engineers about your specific needs.

As individually customized thermal conductive material components, thermal conductive materials are suitable for a variety of thermal management systems to meet the purpose of optimal thermal control for a variety of specific applications.

Trumonytechs thermal conductive mats are vibration dampening and provide adequate protection for electronic components with minimum pressure values between them. You can provide us with minimum pressure requirements and our engineers will meet the custom requirements for your specific application. Effective thermal interface between the electronic components to ensure adequate heat transfer between the electronic components.

At Tronytechs, we also ensure that you get the right thermal conductive mat product for each application. Our application specialists work closely with our customers to specify the right thermal pad material for each unique thermal management requirement.

- The thermal conductive pad we supplied is in a wide range of thermal conductivity, the high thermal conductivity 12W/m*K pad already achieved mass production here. Moreover our thermal conductive pad can be kept for 10 years and remains stable performance.

- Thermal conductive pad can fill tolerances between the heatsink and the cooling components, thus there’s more flexible craft demand for cooling parts.

- Thermal conductive silicone pad has good insulation properties, generally up to 10Kv/mm or more.

- The another function of thermal conductive pad is vibration damping and sound-absorbing which can efficiently reduce the noise of machine operation.

-

Thermal conductive silicone pads offer the ease of installation, testing.

Trumonytechs production and development of thermal conductive mats in performance, structure and thermal conductivity are tested in many aspects, the overall performance are all unique. No matter what your needs are, we can find the right pad for your environment. Choosing the right pad not only provides an excellent thermal interface for the heating element, but also enhances the safety and reliability of the component. We offer thermal conductive mats with the following characteristics:

- Insulation

- High thermal conductivity

- High fit performance, even on uneven and rough surfaces

- Multiple hardness and thickness options for a variety of applications

- Suitable for a range of thermal conductivities

- Slight viscosity allows for pre-assembly

- Excellent aging resistance

- High interfacial gap filling capability

- Excellent temperature resistance

Generally speaking, the thickness of the thermal pad is directly proportional to the cooling effect, the thinner the thickness of the pad, the worse the thermal performance, Tronytechs offers thermal pads generally in the range of 0.010 inches to 0.250 inches. They can effectively fill various gaps and increase the overall thermal conductivity. We also offer a variety of thicknesses and configurations customized to meet the needs of different industries.

Trumonytechs thermal interface products are well suited for a variety of industries and applications. They are used in many types of assemblies in electronics, telecom, automotive, medical, aerospace and satellite applications, among the industries where we excel are:

- New energy automobile industry: generally recommended to use the thermal conductivity between 1.5~3W/m*K, its advantages are low cost, thermal conductivity range can meet the needs of the core operation, thickness is generally recommended to be 0.4~3.5mm thickness, hardness is generally recommended shore 00 25~45, according to the customer core structure to make the selection.

- 3C industry: generally recommended thermal conductivity of 5 ~ 8W/m*K, thickness is generally selected as 0.5 ~ 1.0mm

- 5G communication/server industry: thermal conductivity of 5~12W/m*K is generally recommended, according to the customer’s heat generation and heat power to make specific recommendations, thickness is generally selected as 0.5~1.0mm.

Trumonytechs is based on Shanghai Jiaotong University, with a scientific research team led by Professor Qiu, who is one of the thousand people in China, with strong R&D strength and rich experience in the application of thermal conductive gaskets.With our first-class R&D facilities, we can design according to the customer’s needs, such as the power consumption of the heat sink, the operating environment, the optimal operating temperature and extreme operating temperature of the device, and other indicators.