Vmets

Vmets - Ultrasonic Assisted Oxidative Desulfurization Plant

FromVmets

VMETS UAOD technology is applicable to different petroleum products including natural gas liquids (NGL), gasoline, kerosene and diesel, reducing the Sulphur content to 10 parts per million (ppm) or less, meeting or exceeding the ultra low sulfur (ULS) transportation fuel standards of most countries and successfully reduced sulfur content in refined oil products by at least 97%.

Most popular related searches

desulfurization plant

natural gas liquid

desulfurization

transportation fuel

fuel desulfurization

fuel standard

fuel sulfur

carbonization

oil refining

desulfurization system

Technology Highlights

- Ultrasonic decreases oxidation reaction time and increases sulfur conversion efficiency with very low residence times (

- The oxidized sulfur compounds after treatment exhibit high solubility in water allowing for easy separation of the sulfur from the hydrocarbon stream.

- Instead of complex post-processing separation, removal of the oxidized sulfur compounds can be achieved via a basic water wash.

- Resulting treated hydrocarbon stream has a sulfur content of 10 ppm and potentially less

- More cost effective than traditional hydrodesulphurization (“HDS”)

Process Flow Diagram

- Capacity: 6,000barrels per day oil with double lines

- Size: 20’X6’

- Operatingcosts: $1.50 per barrel including power, ultrasonic wearable parts and catalyst

- Powerrequirements: 75 – 95 KWatts at 480 Voltage, 3 Phase for double line unit

- Lifecycle: 20years excluding wearing parts

Desulphurization Relative Difficulty

Sulfur in refined fuel streams generally occurs from the following compounds:

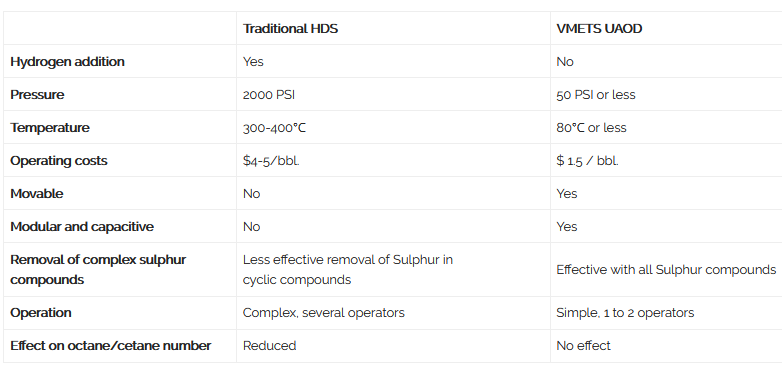

Challenges of Traditional Hydrodesulphurization (“HDS”)- Capitalcosts: high

- Operatingcosts: high utilities, labour, catalyst use, hydrogen

- Operatingcomplexity: high pressure, high temperature, safety

- Efficiency:less effective at converting complex cyclic sulfur compounds

- Carbonfootprint: hydrogen use and energy (heat/pressure) use

- Capital costs: lower relative to HDS

- Operating costs: low utilities, lower labor, catalyst cost and regeneration use, no hydrogen

- Operating complexity: low pressure, low temperature, safe

- Efficiency: very effective at converting complex compounds abundant in hydrocarbon streams

- Carbon footprint: lower energy use

Benefits of VMETS UAOD Technology

- Cost effective, scalable solution to developing market for hydrocarbon fuel desulphurization

- Applicable to a broad range of feed fuels (gasoline, naphtha, diesel, marine fuel, etc.)

- Economic and regulatory demand drivers

- Carbon footprint minimization

- Proven technology: commercial trials have demonstrated effectiveness of process, scalability and commercial readiness