- Home

- Companies

- Remington Valve

- Products

- Remington - Model S-Series - Valve for ...

Remington - Model S-Series -Valve for Power Generation

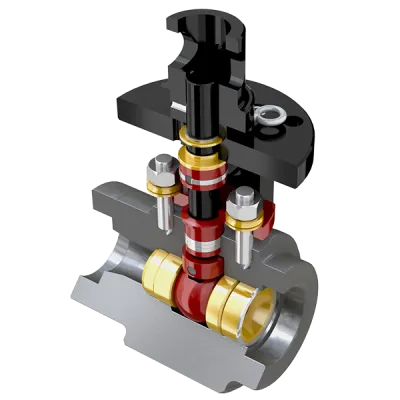

The Remington S-Series Valve is engineered for power generation and steam applications, providing an economical solution with precision design. This unibody valve integrates Remington's metal seated ball valve technology, using the same base material for both the ball and seat. This ensures consistent thermal expansion and maintains sealing integrity, minimizing the risk of leaks by eliminating gaskets or joints. The S-Series features live loaded packing, anti-extrusion, and lever-operated handles. It includes a double collar dual blowout proof stem design to prevent stem ejection. The valve's flow path is optimized for maximum Cv, and it is easily automated, suitable for compact installations. The valve's pressure class ranges from 150 to 4500 ANSI and is available in sizes from ½ to 2.5 inches. It serves critical functions such as isolation, venting, and drainage, making it especially effective in power applications.

Remington’s S-Series line is specifically designed for use in power generating services. Quarter turn efficiency combined with durable, long-lasting coated surfaces allows customers an affordable alternative in steam services.

SIZES

½ – 2.5 “ (2-3 PIECES)

PRESSURE CLASS

APPLICATIONS

- Critical Isolation

- Vents

- Drains

- Blocks

- Specifically Designed for Power Applications

The S-Series is our economic valve designed for power generation/steam applications. The S-Series is a unibody design which incorporates all of the aspects of our metal seated ball valve sealing technology.

The ball and seat are the same base material, meaning they thermally expand at the same rate and hold the sealing area intact. The design eliminates gaskets or joints in the valve, reducing the chance of gasket leaks or seal leaks.

The S-Series features live loaded packing, anti-extrusion, lever operated handles, worm gears and a ISO mounting pattern on the mounting pad for actuation. The double collar dual blowout proof stem construction design on this product prevents any chance of the stem blowing out of the valve. A lever or a T-handle is included for easy operation in tight areas in limited space areas. Our flow path through the valve is optimized to give the maximum Cv possible through the given bore sizes.

The valve is easily automated serving the power industry with compact design, and it is the most economical valve to use in steam services in power generation applications.