SolarLab - Ventilated Building Integrated Photo Voltaic (BIPV) Facade Cladding System

Replacing the exterior rain cladding with photo voltaic cells creates a true Building Integrated Photo Voltaic facade known as BIPV. Photo voltaic cells are temperature sensitive and their power output as well as their lifespan is reduced at higher temperatures, so our facades are designed to allow natural air ventilation to cool the panels while providing a highly durable sun and weather screen to the underlying building structure. The SolarLab BIPV solution can be customized to fit any facade and is therefore used both in new buildings and as rainscreens in energy renovations. The facade panels are made from coated and tempered low-iron glass laminated with high quality PERC c-Si photo voltaic cells, before being assembled into the finished facade system.

Our integrated production takes place entirely in Europe and provides an extremely flexible and responsive production pipeline with a very low LCA, as we strive to manufacture using purely sustainable energy sources and minimizing unnecessary transport.

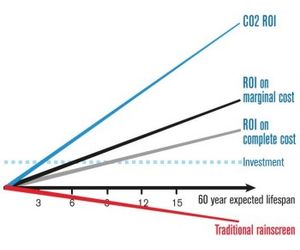

Depending on location and orientation as well as the local source of electricity, a BIPV facade will return the energy and carbon dioxide investment accrued during its creation in just a few years. It will also have paid for the marginal cost of the system, while, of course, continuing to produce sustainable and free electricity for many years to come. This makes BIPV facades one of the best investments available with a very high ROI – and the only building material to do so.

As Passive House and ZEB projects often require onsite energy production our BiPV facades are often cost-neutral to placing traditional loc-cost system on the roof and will free up flat roofs to be utilised for activities and rainwater management.

Panels manufactured using the same technology and materials are known to still be in production 60 years after they where originally installed.

Our BIPV facades are supplied as complete systems, to be installed by a local installer under our supervision. If required, SolarLab can, however, also facilitate the installation and commissioning through our network of local installers. The facade cladding system includes all mounting and electrical components to install and connect the system electrically.

The SolarLab cladding systems are designed for low energy footprint, longevity and ease of installation as well as service. A low installation weight of only 13 kg/sqm has been achieved to ensure the systems can be installed anywhere and by a single person if necessary.

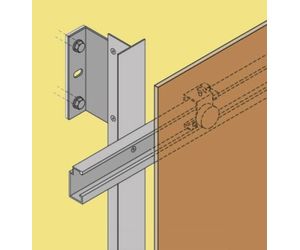

SolarLabs ventilated and light weight BiPV facades leverage existing, familiar and well proven technologies and combine these with our proprietary mounting systems and custom tailored cladding panels to provide easy to install and resilient facades. This de-risks the process and facilitates a quick learning curve with predictable outcome and lower costs.

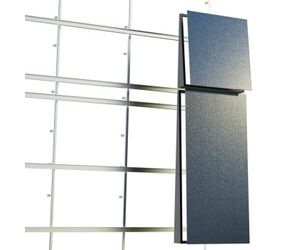

Fundamentally the BiPV facade cladding consists of 3 structural layers. The outer skin that is based on well proved and resilient PV technologies, but where SolarLabs production allows a broad scope of customization in colors, finishes and dimensions. The proprietary mountings system is the foundation that securely attaches the BiPV facede to the underlying building structure and allows for fast, sequre and easy installation on any building. Finally the middle layer that provides the geometric flexibility to tailor panelisation and individual panel level orientation.

Typical scope boundary for the SolarLab facade is the supporting wall surface or the vertical girts, where we mount our horizontal rails. On the electrical side the scope boundary is typically the AC side of the 3-phase inverters and the web based monitoring interface.

Our EU based production pipeline allows us to both be incredibly flexible and responsive, but also a high degree of project specific customization, as described above and we are always ready to help an explore ways to provide just the right solutions for your project and answer any questions that may arise in the concept and design phases.

To get you started we provide our design guidelines for typical BiPV facades in a PDF below, along with a product description flyer to help communicate to stakeholders, colleagues and clients, the opportunities that a custom BiPV facade from SolarLab provides. When you are ready we are always open to meet and give feedback, as well as to take it to the next level and make it a reality.

The SolarLab facade system is a genuine BIPV (building integrated photo voltaic) solution to replace the traditional rainscreen. The system is suitable both for new constructions and rejuvenation of older buildings.

The system consists of 3 core components; the outer facade panels, the mounting solution and the electrical system that connects the BIPV system to the building’s electrical system.

SolarLab delivers the complete installation and it can be installed by a local façade installer or by SolarLab’s own specialists. The BIPV facade is connected electrically in groups with similar shadow conditions, and to inverters that generate either single or triple phase output and feed into the building’s regular AC grid in accordance with local code and regulations. To de-risk the installation our system is designed to be comparable to known facade cladding and PV systems, so contractors have no surprises and local approval is easy.

With both active panels containing photovoltaic cells that generate electricity, and inactive panels that look identical and are equally durable, the system can be used cost-effectively over the entire building without compromising the architectural design.

The SolarLab facade system is produced specifically for each project in accordance with the projects specifications and wishes thus allowing owners, developers and architects the freedom to select color, finish, size and shape of the panels. Due to our low LCA this facade system allows the project owner the opportunity to create Net-Zero buildings and to optimise for DGNB and LEED certification, with a facade cladding that pays for itself.

The reality is that it is hard to find better environmental and financial investments than BIPV, as it recoups the CO2 and energy investment in just a couple of years and continues to generate free electricity for 60-80 years, completely carbon-free. Depending on the local cost of electricity and energy source that it replaces, the marginal cost of BIPV over a classical facade cladding enables financial ROI’s of more than 10% annually over the full 60-80 year lifetime of the installation.

Facade cladding with photo voltaic cells is basically constructed as any other PV panel. The only difference is the finishing and coating of the front glass along with the mounting system that is based on recognised and proven technology and components that have been thoroughly tested.

Our high quality low-iron glass is finished on the front to create the desired reflectivity or surface texture and coated on the back with a PVD coating or glass based frit to create the desired colors and patterns. As the butterfly’s wings create colors without pigments, our PVD coatings have the unique capability to allow most of the light through to generate electricity while at the same time creating a dynamic and colorful reflection by returning only specific wavelengths depending on the light’s incident of reflection.

The photo voltaic cells we use are always the best performing cells available commercially, and currently this is HJT or PERC Mono c-Si cells, but we have a range of options to fit individual project requirements from half-cut cells to multi-crystalline cells. The use of high quality cells in our facade cladding makes it one of the highest performing on the market providing up to 185 Wp per squaremeter, making Net-Zero possible without externalising the energy production.

The system is extensively tested to ensure strength and endurance. The tests are based on the DS/EN 1991-1,-3 and -4 (Eurocodes for wind and snow load, as well as accompanying national annexes). We continuously test components and the system as part of local approvals to insure compliance.

Solarlabs production is entirely in Europe and our experienced and well trained production staff ensures that every component, panel and assembly leaving our factories is tested and compliant. Both production and products are certified in accordance with international standards, and are inspected by TÜV at yearly inspections to ensure compliance with IEC EN 61215, IEC EN 61730-1,-2, IEC EN 62716 Ed.1, IEC EN 61701, IEC TS 62804-1 (PID resistance).

Buildings and their construction account for 36% of the global energy use and 39% percent of the CO2 emissions, but according to the IPCC the resource consumption of buildings can be reduced by 46%. The EU, California and many other governments around the world has therefore made it an obligation that building of the future must be Net-Zero.

Energy producing facades have a great role in achieving this by replacing traditional rain-screens and freeing up roofs for rain absorbing greens and activities. BIPV facades also has the added benefit that energy production coincides with load patters as moders energy efficient and well sealed houses with large windows will need to continuously ventilation for health and comfort.

Under Danish conditions, the BIPV facade will recoup the energy and CO2 investment of its creation in just 2 to 3 years, and during its expected 60 to 80 year lifespan the panels will continue to produce carbon free energy. Add to this the energy and CO2 saved by eliminating the production of the bricks, concrete or metal facade replaced by the BIPV and the ROI calculation only gets better. Unique to BIPV as a building material, is the fact that it pays for itself and continues to contribute for many years.

SolarLab produces and assembles all its systems in Europe using state-of-the-art machines and sustainable energy from hydro, sun and wind. Sourcing high quality materials and components locally with a high recycled content we further aim to minimise transport distances and waste. This has a large impact on LCA, CO2 footprint and Energy PayBack Time (EPBT) as our facades and panel have 2-3 times lower LCA than Asian products produced with fossile energy.

SolarLabs energy producing facade system replaces a traditional rain-screen and provides the building’s facade. Each facade is tailor made providing extensive design freedom in dimensions, shapes, finish and colours. This architecturally aesthetic and attractive product is supplied as a complete solution and can be mounted by any contractor with experience in facade installation and connected by electricians with regular PV experience.

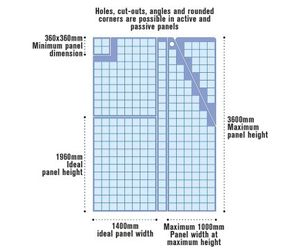

Due to our use of high performance HJT or PERC mono c-Si PV cells, the system is passively ventilated to keep the cells cool as production decreases with higher temperatures of the cells. This ventilation 50 mm gap is our minimum build height and the maximum is around 350 mm. The PC cells are square impose a modularity to the design of panels, but we can always just add glass to meet size requirements in a project. Our preferred minimum panel size is 360 mm, but no larger than 3600 mm to a side and we generally find that panels around 2000 mm by 1400 mm work really well in production and during installation as the weight and proportions allows single operator installation. The weight is around 13 kg per square meter, fully installed.

The wide range of solutions and project specific customisations to finish, texture, colours, character and mounting makes the cost dependent on the complexity of the facade and the installation conditions, but is generally between 375 and 475 Euro per square meter as a complete turn-key solution. These prices are based on a 1000 squaremeter facade with 30% inactive panels fully installed and including both electrical system and commissioning.

The system consists of 3 primary components; an outer skin of durable glass, supported by a mounting system made from aluminium as well as the electrical inverter and control systems. All these provide flexibility to design the right solution for each project. We support with design and engineering experience thought out the realisation process, so the sooner SolarLab is involved the better we can support and de-risk the design intent.