- Home

- Companies

- Ningbo VET Energy Technology Co., Ltd

- Products

- VET - 3kW Methanol Hydrogen Production ...

VET - 3kW Methanol Hydrogen Production Power Generation System

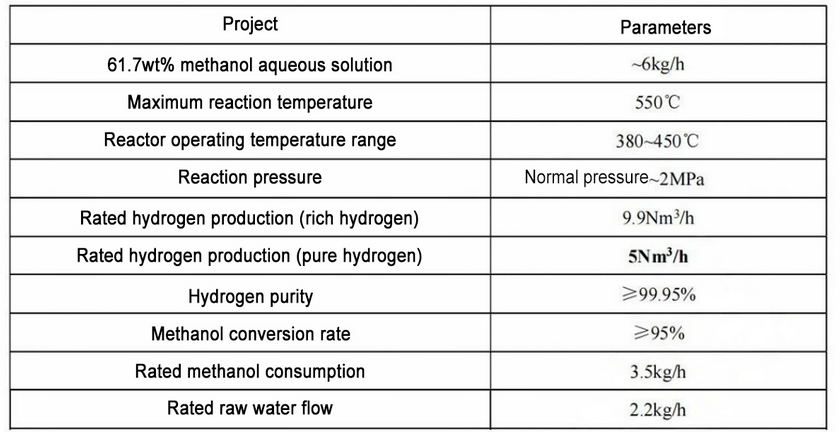

China-Vet`s 3kW Methanol Hydrogen Production Power Generation System is an innovative energy solution, the system is flexible in design, compact and efficient, suitable for a variety of applications from industrial use to remote power supply. By utilizing methanol as a feedstock, the system can efficiently produce hydrogen, reduce environmental impact and promote energy sustainability.

The 3kW Methanol Hydrogen Production Power Generation System from China-Vet represents a cutting-edge solution in the field of clean energy. This system combines advanced methanol hydrogen production technology with efficient power generation, offering a reliable and environmentally friendly alternative to conventional energy sources.

This power generation system leverages hydrogen fuel cell technology to convert hydrogen derived from methanol into electricity. The process is efficient and sustainable, making it an excellent choice for reducing carbon emissions while meeting energy demands. Designed for diverse applications, the system is ideal for use in industrial facilities, remote power stations, and backup energy supplies.

Process Flow

Process Principle of This System:

The basic principle of the equipment process is to use methanol vapor to react with water vapor under the action of catalyst at high temperature to generate crude hydrogen, enter the purifier for purification to obtain high-purity hydrogen, and then use the downstream fuel cell system to power the power unit, or store it in the battery-based energy storage system for standby use.

he methanol water reforming reaction is a multi-component, multi-reaction gas-solid catalytic complex reaction system. Specific chemical reactions may include:

The entire process is as follows: First, the desalted water and methanol are mixed according to the set ratio, and then injected into the reforming hydrogen purification system through a high-pressure infusion pump. After the mixed liquid is rapidly vaporized in the vaporizer, it enters the catalyst bed (400-500 °C) to undergo a methanol steam reforming reaction. The single-pass conversion rate of methanol is usually above 95%, mainly generating 75% H2, 24% CO2 and less than 3% of impurity gases such as CO and CH4, which is crude hydrogen. This crude hydrogen can directly enter the dense metal membrane purifier, which can purify the crude hydrogen into hydrogen with a purity close to 5N, which meets the requirements of proton exchange membrane fuel cells for hydrogen in ISO 14687-2019 and GBT37244-2018 standards. The purified hydrogen can be directly used in the hydrogen unit after the fuel cell generates electricity, and the chemical energy of hydrogen is converted into electrical energy through the fuel cell. The generated electrical energy can be used for external power supply or stored for standby through a lithium battery-based energy storage system. The process flow is shown in the figure below: