- Home

- Companies

- Guangzhou Shincci Energy Equipment Co., ...

- Products

- Waste Heat-Type Thickner

Waste Heat-Type Thickner

Applicated In: continuous evaporation concentration in industries such as milk, glucose, amino acids, starch, xylose, pharmaceuticals, chemicals, bioengineering, environmental engineering, and organic solvent recovery, making it particularly suitable for materials with thermal sensitivity, viscosity, and foaming properties.

Advantages: Low temperature evaporation in range of 20~60 degrees (one-effect to four- effect) and effectively maintain product ingredients.

Adopt four-effect evaporation and concentration design , which saves 75% energy comparing to one-effect evaporation.

Multi-stage low-temperature evaporation concentration can effectively control discharge concentration, and live concentration monitoring control can realize automatic discharge.

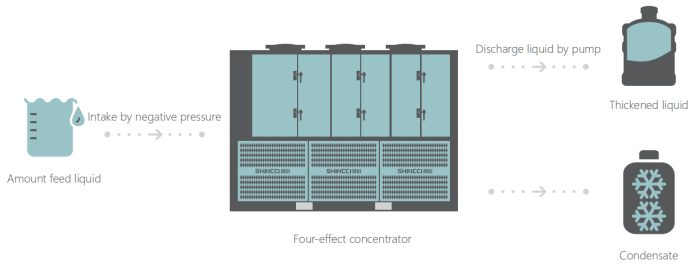

A large amount of feed liquid is intake by the concentrator machine under negative pressure, and a small amount of thickened liquid is discharged by pump after treatment; condensed water is forced out by the water pump.

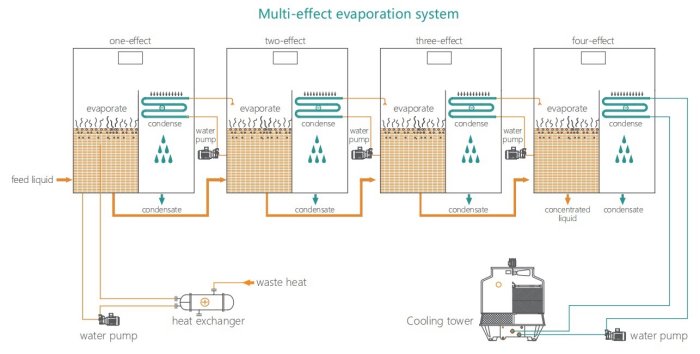

The one-effect feed liquid is heated by the heat source in vacuum and then boils and evaporates, and the low-temperature steam is cooled into condensate by the two-effect condenser and discharged outside the machine

After being concentrated by the one-effect evaporation, the feed liquid enters the two-effect evaporation chamber. The two-effect feed liquid is heated by the two-effect heater and then boils and evaporates. The low temperature steam is cooled into condensate by the three- effect condenser and discharged outside the machine

The feed liquid enters the three-effect evaporation chamber after being concentrated by the two-effect evaporation. The three-effect feed liquid is heated by the three-effect heater and then boils and evaporates. The low-temperature steam is cooled into condensate by the four-effect condenser and discharged outside the machine

After concentration by three-effect evaporation, the feed liquid enters the four-effect evaporation chamber. The four-effect feed liquid is heated by the four-effect heater and then boils and evaporates. The low temperature steam is cooled into condensate water by the cooler and discharged outside the machine

The cooling heat is discharged from the engine through the cooling system

The feed liquid passes through one- effect, two- effect and three-effect. After multi-effect concentration, it is discharged outside the machine.