- Home

- Companies

- Aerzener Maschinenfabrik GmbH

- Products

- Aerzen - Model Series VRW - ...

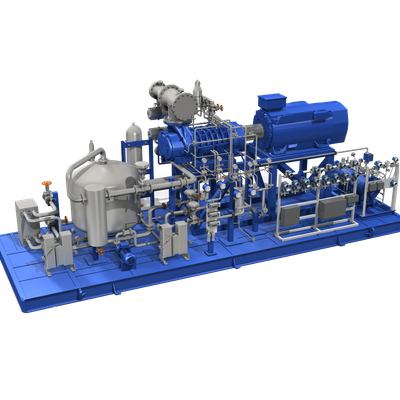

Aerzen - Model Series VRW -Water-flooded Screw Compressor

Bringing large H2 volume flows to the highest possible intermediate and final pressures with just a few compressor stages, without having to set up huge reciprocating compressor systems for this purpose - precisely here is where the new VRW 536 M oil-free screw compressor from AERZEN comes in.

- Volume flow: 370.818 to 3.531.6 CFM

- Differential pressure (Δp): 43.51 to 130.53 psi

- Medium: Hydrogen

- Compression: Oil-free

The advantages of AERZEN VRW Screw Compressor at a glance:

- 100% oil-free compression

- Maximum efficiency and increased differential pressure in one stage

- Minimisation of installation area

- Reduced investment and operating costs

- Pre-drying of the wet H2-gas is not required

- Ideal as a pre-compressor (booster) for the following compressor types

Hydrogen compression at the highest level

The new VRW type oil-free compressor has been specifically designed to compress wet electrolysis hydrogen with unprecedented efficiency and differential pressure.

The VRW follows the dynamic operation and the special requirements of the most modern electrolysers, whether alkaline technology (AEL), proton exchange membrane (PEM), or high temperature (SOEL).

As a pre-compressor for large quantities of H2 from atmospheric electrolysis, the VRW provides downstream compressor types with the inlet pressure that reciprocating compressors in particular require for economical machine designs.

Applications:

- Green hydrogen

US Units: No

- Type of technology: Screw Compressors

- Differential pressure (Δp): 43.51 to 130.53 psi

- Volume flow: 370.818 to 3.531.6 CFM

- Medium: Hydrogen

- Compression: Oil-free

Technical Properties - The New H2-Compressor Concept

- Water-flooded for cooling the gas and for gap sealing (efficiency increase)

- Stainless steel design for maximum service life (corrosion resistance)

- Water-purged mechanical seals at the conveying chamber for 100% oil-free compression

- Oil-lubricated roller bearings for maximum speed range

- Speed control for adaptation to fluctuating process conditions

- Gear-synchronised rotors (no contact with the rotors)

- Designed for three-year revision cycle (MTBO)

- Directly coupled or with gear ratio