- Home

- Companies

- Innovas Technologies LLC

- Products

- INNOVAS Triton - Y-Strainer for Energy ...

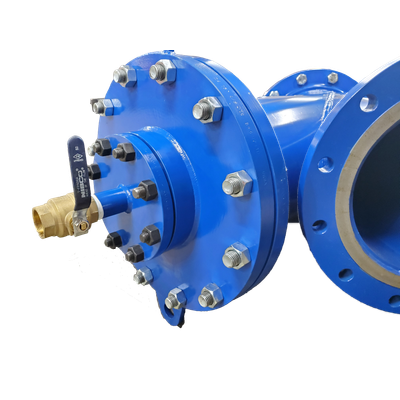

INNOVAS Triton - Y-Strainer for Energy Efficient Fluid Management

The Innovas Triton™ High Efficiency Y-Strainer represents a significant advancement in fluid management technology. It is engineered to maximize energy efficiency by employing a unique design that enhances fluid flow and minimizes pump energy consumption. The strainer boasts a 20% larger screen surface area compared to conventional wye strainers, allowing for prolonged operation between cleaning cycles. This innovative approach reduces pressure drop by 300% and operational costs by half, supporting sustainability initiatives, including NetZero goals. Customizable in terms of materials, dimensions, and connectivity options, the Triton™ Y-Strainer is entirely designed and fabricated in the USA. Built to rigorous ASME standards, it ensures reliable performance and improved safety with reduced maintenance requirements. With its QUIKCLEAN™ service port and proprietary screen design, the Triton™ Y-Strainer is ideally suited for demanding applications where both efficiency and reliability are paramount.

Traditional wye strainers utilize a bridge wall or plate to retain the strainer screen and divert flow into the strainer—which greatly disrupts the fluid flow, causes pressure loss, and results in increased pump energy consumption. Triton™ Y Strainers employ a proprietary design enabling streamlined fluid flow and resulting in much lower pump energy requirements.