Curran - Heat Exchanger Release & Protective Coatings

Curran International is globally known for its thin film exchanger coating applications to reduce fouling and corrosion. For more than 25 years Curran has applied heat exchanger internal coatings to extend operating reliability; Curran tube ID coating eliminates or inhibits fouling in heat exchanger tubes. Using proprietary application technologies, Curran has become the world leader in holiday free heat exchanger coating using advanced polymers applied in a uniform thin film.

Full length coated tube ID applications were demonstrated by Curran at a US power utility where a condenser suffered from accelerated cooling water tube corrosion. The utility, together with the Electric Power Research Institute (EPRI), began to research use of epoxy for heat exchanger coating to mitigate water scale deposits. The study verified the efficacy of heat exchanger internal tube coating.

The benefits of tube ID coating are known by refinery and petrochemical clients across the globe. Refinery bad actor bundles are likely poor performing exchangers due to the effects of fouling in heat exchangers. Equipment engineers specified heat exchanger coating to replace “in-kind” fabricated tube bundles using Curran tube ID coating; benefits were found in years of reduced maintenance, continuous operation run, and improved operating reliability.

Curran is at the forefront of material and application technology development using advanced polymers and inorganic/hybrid coatings. Ultra thin (

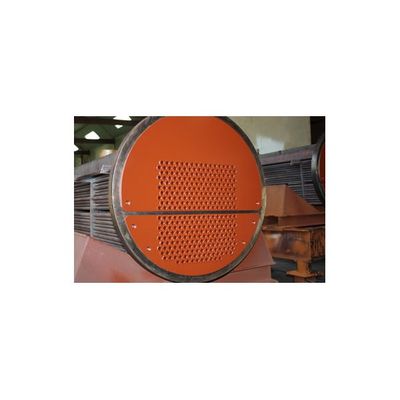

All heat exchanger internal coating applications are subject to Curran quality control, and inspection observation and record points. We coat shell & tube exchanger bundles, air coolers, U tube and plate and frame exchangers; provide in-service exchange tube ID restoration; tube end coating, plate exchangers, OD tube coating; in-situ and field coating applications.

Curran has mastered surface prep and application methods for coating in-service exchangers, this technique is used to restore exchangers for continued service. Curran can achieve NACE 1 white metal cleanliness of in-service exchanger tubes, and its application methods satisfy holiday spark testing requirements – even in pitted tubes. A homogeneous thin film coated tube mitigates fouling in heat exchangers and prevents tube ID corrosion.

- Reduce fouling

- Precipitate scaling

- Mitigate corrosion and velocity erosion

- Eliminate routine exchanger maintenance

- Extend useful life of exchangers

- Reduce head pressure

- Energy savings (support Energy Exchanger initiatives)

Curran 1000 – Advanced two-part 100% solids epoxy coating designed for high temperature immersion service in cooling water, hydrocarbons and process streams. This coating is an organic/inorganic hybrid with superior mechanical performance; resistant in cooling water steam services to 365°F and excursions to 400°F (204°C). Applied to 8-14 mils total DFT.

Curramix 2500 – An ultra-low DFT ambient-cure coating system designed for high temperature fouling services; excellent hydrophobic & oleophobic properties, anti-coking performance, resistant to thermal cycling, and can be used in 1200°F. May be applied to heat exchanger tubes, plate & frame exchangers. Applied to 20-40 microns total DFT.

Curramix 3500 – An advanced anti-coking ceramic coating for crude and hydrocarbon fouling; excellent hydrophobic & oleophobic properties, anti-coking performance, resistant to thermal cycling, and maintains repellency to 750°F. Applied to heat exchanger tubes, plate & frame exchangers. Applied to 12 to 38 microns total DFT.

Baked Phenolic – Shop applied, bake catalyzed, suitable for all cooling water services, hydro carbons, salt solutions and solvents. Immersion resistance to 365°F; applied to 7-10 mils total DFT.

PFA and PTFE – Shop applied, bake catalyzed fluoropolymers; superior resistance in chemicals, solvents and acids. Immersion resistant to 500°F. Applied to 8-14 mils DFT.

StreaMax™– A Chemours recommended material for Heat exchanger applications, shop applied fluoropolymer; bake catalyzed, uniform adhesion; reduces surface roughness and drag, low friction coefficient. Excellent non-stick and product release, for some services up to 500F.

Sol Gel – Ceramic SiO “backbone” hybrid with organic and inorganic components, suitable for plate & frame, and tube bundles in process critical services. Applied to 20-40 microns total DFT.