- Home

- Companies

- Pro Enviro Ltd.

- Services

- Design, Installation, Commissioning

Design, Installation, Commissioning

Pro Enviro prides itself on its depth of technical knowledge and commitment to fulfilling the needs of our clients. We have therefore built the capacity to provide design, installation and commissioning services for the full range of energy, power, mechanical and lighting systems our clients require, including renewable energy systems. We can simply provide expert project management support or deliver a full turnkey service using suppliers that our clients already work with or brought from our own framework of trusted installers and suppliers.

On average, 25% of an organisation’s electricity costs come from lighting. With energy efficient lighting you can cut these costs by up to a third while reducing your carbon footprint and improving the working environment for your staff.

CCFL bulb

Focusing on low and no-cost measures and actions which will have the quickest payback, this overview explores some of the main types of lighting and demonstrates the best energy saving opportunities available. Pro Enviro can provide the following:

Reduce the need – the design and specification of lighting systems have a big impact on energy use and hence, energy spend. Sometimes nature provides the best solution to lighting needs.

Good housekeeping and people issues – the way occupants use a lighting system plays a big role in how it performs.

Maintaining existing systems – regular maintenance is vital for maximising energy savings and maintaining a comfortable working environment

Understanding and using controls – learning how to set and regulate lighting controls can provide substantial savings and enhance comfort conditions for building occupants.

Upgrading and refurbishment – there are some excellent opportunities for energy saving whenever upgrades or refurbishment is planned. New efficient equipment can often pay back its costs very quickly.

The lamp is central to any lighting system and choosing the right one is vital for maximising savings. The light from each type of lamp can be defined in terms of colour, brightness and warmth. Lamps can also be compared by their efficiency and life. There are two main categories of lamp which create light differently: filament lamps and discharge lamps. A third type, light emitting diode (LED), is outlined below, although not discussed extensively here as this is emerging technology which is not utilised widely in business applications at present.

Filament lamps

The filament has high resistance to electricity. Light is produced when the filament gets so hot it glows. This is a fundamentally inefficient method, producing more heat than light. This is the way all ‘traditional’ tungsten light bulbs work. A variant of this is the tungsten halogen, which also employs a filament, but in a bulb containing halogen gas. Filament lamps are very common, although their poor efficacy means that they are increasingly being replaced with more efficient alternatives such as compact fluorescent lamps.

The most common types are known as general lighting service (GLS) lamps and decorative lamps. The majority of luminaires in most homes use incandescent tungsten metal filament lamps. All filament lamps will reach maximum light output the instant they are switched on, provide good quality, accurate colour rendering and can be dimmed. However, they are expensive torun and produce high levels of unwanted heat. They also have high maintenance costs associated with their relatively short 1,000-hour lamp life. Main applications: Although these are relatively inefficient bulbs, they are found extensively in homes, and businesses alike.

Discharge lamps

Electricity creates a charge which, when applied to a gas filled lamp at the correct voltage, causes the gas to emit energy. Most of this energy is light but some heat and noise is also produced. To obtain and maintain the correct voltage, additional control gear called a ballast (or sometimes ‘starter’ or ‘choke’) is needed. This is how most non-tungsten lights work including fluorescent, sodium metal halide and mercury.

Tubular fluorescent lamps have 4-10 times the efficacy (dependent on wattage/size) of incandescent lamps and can last up to 18 times longer. Compact fluorescent lamps (CFLs) often look like standard tungsten filament lamps, but work much the same way as fluorescent strip lighting, in that they require an electronic ballast to start and the inside of the tube is coated with phosphor that gives off the light. Triphosphor versions of both are available, which are more efficient, have a longer life and maintain their light output levels better than ‘standard’ halophosphate lamps. Special ballasts can be employed so they can be dimmed. Main applications: Used in offices and commercial buildings and most low bay industrial applications (that is, at heights below 5 meters). Compact fittings mean they can replace traditional tungsten lamps directly.

Light emitting diodes (LEDs)

Light emitting diodes (LEDs) can be very efficient, relying on a pure semi-conductor to emit light (but not heat or noise) as a response to an electric current. At the moment, common business applications include illuminated signs, such as emergency lighting, for which they are excellent. Recent advances in the technology have led to a new generation of LEDs which offer better colour properties than previous models and, often, can be fitted directly into existing fittings. This could mean that LEDs are appropriate for a wider range of applications. To explore these options, contact a specialist manufacturer.

Benefits of an Energy Efficienct Lighting System

As a major use of energy within a company, changes in lighting have the following advantages:

- Lower energy usage

- Reduced replacement costs

- LED bulbs are not hazardous waste and can reduce waste costs as a result

Electric induction motors run at fixed speeds and are ideally suited to applications where a constant motor output speed is required. However, there are some applications where varying motor output speeds are preferable, better meeting the requirements of the load.

A variable speed drive (VSD), also known as a frequency converter, adjustable speed drive or inverter, is an electronic device that controls the characteristics of a motor’s electrical supply. Therefore, it is able to control the speed and torque of a motor, achieving a better match with the process requirements of the machine it is driving. So in applications where variable control is desirable, slowing down a motor with a VSD does reduce energy use substantially.

VSDs are supplied in a wide range of sizes from 0.18kW through to several MW and may be optimised to suit particular applications. VSDs are typically 92–95% efficient with 5–8% losses being due to additional heat dissipation caused by the high–frequency electrical switching and the additional power required by the electronic components.

The losses are usually more than compensated for by the savings at the motor. The motor itself also has various internal losses and, if it is attached to a transmission system of some sort (for example, a gearbox or pulley), then this introduces further losses in the form of friction. So, typically, only 75–80% of the energy supplied to the motor system is transmitted to the end–use equipment.

The majority of these losses appear as heat. A drive can be located inside an enclosure, some distance away from the motor itself, or it can be directly attached to it. One thing to remember is that if equipment is located in a particularly dirty or badly–ventilated area, then it is advisable to relocate the drive to a suitably protected area. This should be an area which is clean, dry and of a suitable temperature to allow adequate cooling. Larger drives can generate quite a lot of heat, and this needs to be removed or the unit will eventually overheat and fail.

A recent trend among motor manufacturers has been to develop a motor with an integral VSD. These packages are typically available in sizes ranging from 0.75kW through to 11kW. The major advantages include:

- Reduced control panel space

- Simplified installation

- Straightforward electromagnetic compatibility compliance

- Integration of motor and drive

These can lead to greater cost savings over the life of the motor. In terms of efficiency, integrated variable speed motors have the same energy saving benefits as a non– integrated motor and VSD. However, because they are compact and easy to install, integrated types are becoming ever more popular in the heating, ventilation and air conditioning (HVAC) and pumping markets.

Switched-reluctance drives consist of a switched-reluctance motor and dedicated electronic controller. Their performance is similar to that of a conventional induction motor and VSD. In addition, they are capable of very high–speed operation (up to 100,000rpm). These devices have an energy efficiency performance similar to, and in some cases exceeding, that of an induction motor with a VSD. However, they are a relatively undeveloped technology and, as such, are much more expensive. Other disadvantages of switched–reluctance drives are:

- They can be very noisy

- They require an electronic controller to work.

- If any faults develop, operation of the whole unit is affected, whereas an induction motor can keep running (albeit at full speed) if its VSD develops a fault.

Switched–reluctance drives tend to be used in niche markets, such as in some washing machines.

DC drives consist of a DC motor and dedicated electronic controller. DC motors/drives operate from a different type of electrical supply than AC motors/drives and as such have different characteristics. Some of the benefits of DC drives are:

- They are less complex than AC drives with a single power conversion from AC to DC

- They are usually less expensive for most power ratings

- They have a long tradition of use as adjustable speed machines, so a wide range of options has evolved for this purpose

- DC regenerative drives are available for applications requiring continuous regeneration for overhauling loads such as driving shears. AC drives with this capability would be more complex and expensive

- They are capable of providing starting and accelerating torques in excess of 400% of rated power and so may be more appropriate for applications such as starting up a mixer while it is full

- They tend to be quieter than some AC drives which may produce audible motor noise, which could be undesirable in some applications.

However, there are some disadvantages when compared with AC drives:

- DC drives tend to require more maintenance than AC drives

- AC motors are better suited for high–speed operation (over 2,500rpm) since there are no brushes, and commutation is not a problem

- Special AC motor enclosure types are more readily available at lower prices when the operating environment is wet, corrosive or explosive.

Efficiency-wise, the performance of DC drives is similar to that of a conventional induction motor with a VSD. DC drives were the main form of variable speed control before the advent of VSDs. They are still in use today in specialist applications where high starting torques and variable speeds are required, such as pulsating loads, shears, bending rolls, plunger pumps, conveyors, elevators and crushers.

Voltage optimisation is used to reduce the supply voltage applied to a single piece of equipment or machinery, specific areas of the business or the building as a whole. By matching the supply voltage to the specific needs of the equipment it is possible to reduce the amount of energy used and extend the life of the connected equipment.

Voltage optimisation

All electrical products supplied in the UK and Europe must be able to operate within 220-245v. This leads to equipment potentially using a much higher amount on electrical energy than is necessary. Voltage optimisation allows the selected equipment to operate at its set parameter rather than a higher rate supplier, leading to reduction in energy used and potential savings.

Savings have been estimated as being as much as 50% on equipment that uses a high supply of voltage e.g. switch start florescent lighting. Unfortunately not all equipment benefits from the same high levels of voltage optimisation and savings vary from 5% to 50%.

Benefits of Voltage Optimisation

Installing voltage optimisation equipment onto machines has the following advantages:

- Increased energy efficiency

- Reduced maintenance cost

Compressed air is a versatile, flexible and safe way to transmit energy. Almost all industrial businesses use it. In fact, over 10% of electricity supplied to industry is used to compress air. However, as much as 30% of this energy is lost through leaking systems — equal to the entire output of a medium-sized power station. Much more is wasted due to compressed air misuse and poor maintenance.

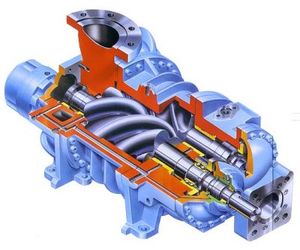

Screw compressor

By the time it reaches the end user, the cost of compressed air can be as much as 50 pence per kWh, compared to around 5-7 pence for ‘normal’ electricity. So it’s important to consider carefully whether compressed air is the best power source for a particular job. Many businesses don’t do this and ‘misuse’ compressed air for processes such as machine cleaning, without realising the cost. Find the appropriate alternative and you could save considerable energy and money.

A well-maintained compressed air system needs less energy to deliver the required pressure. And it’s easy to do.

Change it. It costs just a few pence to replace an intake filter and could save pounds in energy; blocked filters restrict the air flow into a compressor, increasing the power used by 4% and reducing efficiency.

Clean it. Keep compressor coolers, radiators and ventilation grilles clean and clear to minimise compressor power use. The dirtier your process, the more often you’ll need to clean the system.

Cut it out. Remove any redundant and seldom-used pipe work or fit isolation valves.

Reduce it. Is your compressor bigger than necessary?

Compressing more air than you need is very expensive. You can determine your maximum compressed air demand by running all air-powered tools and equipment flat out at the same time and noting the drop in air pressure.

Types of system

Portable units, where the main components are combined in one machine, are the most common. These are generally used for small-scale applications, or when a mobile power source is needed. Businesses with a larger demand for compressed air may use a system with separate units and fixed air line distribution pipe work.

Simple adjustments and improvements to your compressor control can save hundreds of pounds.

Switch it off. An idling compressor can still use 40% of its full load.

Downsize. Determine the minimum system pressure and adjust the compressor accordingly. Ask equipment and tool manufacturers to specify the minimum air pressure that their equipment needs.

Automate. Consider installing an automatic pressure controller: this will ensure you always have the most efficient air pressure setting.

Minimise pressure drops. It’s important to keep the system pressure drop below 0.2 bar. Take a reading of the pressure at the compressor with a pressure gauge and then, using the same gauge, take a measurement at the farthest point on the site. Large pressure drops indicate that the air pipe is too small, stifling the airflow

Improved air treatment. Raising the quality of your compressed air can make a real difference to energy efficiency.

Strike a balance. Having hot, wet or ‘dirty’ air means that the compressor has to work harder. However, treatment itself can use energy, so always treat the air to the lowest acceptable level.

Treat locally. If only a few pieces of equipment require high-quality air, treat at the point of use rather than treating the whole supply.

Stay in good shape. Change filter elements regularly and have any condensate collection system checked regularly to ensure that it’s working effectively.

Waste heat recovery It’s easy to obtain hot water or hot air by recovering heat from a compressor.

Here’s how your business may benefit:

Space heating. You may be able to duct hot air into a workshop or warehouse to provide ‘free’ heating.

Air tempering. If the hot air flow is insufficient to heat the full space, it can still be ducted into the existing space-heating system for preheating.

Keeping things dry. Simply placing a compressor in a warehouse may provide enough heat to prevent product and packing materials such as cardboard boxes becoming damp.

Benefits of a Well Maintained Air Compressor System

- Maintaining air compressor systems has the following advantages:

- Preserve pressure in the system

- Reduce wasted energy and costs