- Home

- Companies

- MAXIMINO BARREIRO SL

- Services

- Welding Services

Welding Services

We have a technical department that collaborates continuously in the different projects allowing planning and controlling the manufacturing phases. We carry out traceability of all projects. We have manufacturing capacity both in the workshop and on-site. We have qualified procedures and welders in different areas (EN ISO 15614 and 15609, EN ISO 3834) as well as a Visual Level 2 Inspector.

The services we have are:

- MIG / MAG / TIG welding. (8 teams).

- Turners / Turners with capacity to weld hips of Ø1200 * 6 m between points.

- Mecano welding of long / short series.

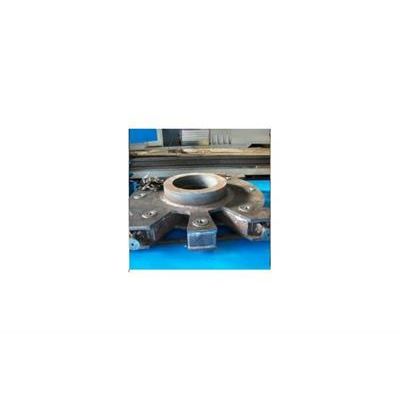

- Recovery of parts by measure of recharges.

- Conventional oven.

- 20T bridge.

Railway welding-machining (EN 15085-2 CL1).

- Bogies

- Boxes.

Manufacture of complete equipment.

- Recycled (Crushers, harvesters, mixers, Hoppers, conveyors)

- Iron and steel (complete lines or parts of the lamination)

- Hydro-Electric. (pleton turbines, francis, kaplan).

Repairs in workshop or on-site. (recharges, retrofitting).

- recharges for roller recovery.

- machinery retrofitting.

Industrial assemblies

- Pipelines.

- Structures

Application rules:

- EN 15085-2 CL1 (Railway Sector)

- EN 9606-1 (Welders Approval)

- EN 15609-1, 15614-1 (Welding procedures).

- EN 14731 (Welding Coordinator)

- EN 3834-2 (Quality Requirements).

- END´S (Visual inspection, Magnetic Particles, Ultrasound, RX)

Maximino Barreiro has 2000 m 2 facilities for boilermaking and welding.

We have extensive experience in the railway sector where we meet the necessary requirements to weld CL1 level components according to EN-15085.

Our team has 8 approved welders and two coordinators who are in charge of qualifying the different welding procedures, necessary for welding carbon steels, different stainless, aluminum etc ...

WELDING EQUIPMENT

- 3 Pronius Trans Plus Synergic TPS-4000 Groups, for any type of material. Digital control knob TIG

- 6 LINCOLN Power Wave 405M welding arc processes, MIG / MAG applications.

- 4 Groups ESAB MIG 5002CV welding arc processes, MIG / MAG applications, and TIG.

- 2 Groups MODULATE 400 A. MIG / MAG applications.

- 1Ud SARTORE 500-A MIG / MAG welding lathe with Ø1600 maximum weight 4000 kg. Simultaneous double torch, and 6 meter longitudinal carriage.

- 100 TN press

- Flame flame