- Home

- Companies

- SmartHelio

- Software

- SmartHelio - AI-Driven Audit Solution ...

SmartHelio - AI-Driven Audit Solution for Solar PV Plants

SmartHelio's AI-Driven Audit solution provides a comprehensive diagnostics tool that greatly enhances the operational efficiency of solar photovoltaic (PV) plants. This one-time diagnostics solution is capable of addressing critical industry challenges such as data quality issues and lack of transparency. Leveraging advanced AI algorithms, it can perform thorough fault analysis and generate detailed health reports. The audit solution is designed to work with any PV plant, regardless of the equipment or location. By utilizing historical data shared via CSV or API, it efficiently creates a digital twin of the plant, extracting essential information including equipment specifications and maintenance reports. The AI-powered system identifies both current and future faults, offering actionable insights and recommendations. Its minimal data requirement and capacity for high-speed processing make it an effective tool for strategic planning and risk management in solar energy operations.

AI-driven Audit: One Time Diagnostics for any plants,anywhere, anytime

SmartHelio’s One-Time Diagnostics tool addresses industry challenges such as data quality and lack of transparency, by leveraging advanced AI algorithms to perform comprehensive fault analysis and generate detailed health reports for solar plants.

- Speed & Efficiency: AI rapidly delivers actionable insights, predicting future failures.

- Minimal Data Needs: AI maps and cleans data with 95% accuracy, generating reports swiftly.

- Comprehensive Fault Analysis: Identifies current and future faults, providing actionable recommendations.

- Transparency & Accuracy: Clear, precise reports streamline negotiations and strategic planning.

NO NEED FOR ADDITIONAL HARDWARE

Onboard AnyPlants, Anytimeusing CSV file orAPI

AI-driven Audit solution can be used for any plants, regardless the equipment used or the location. All you need to do is to share historical data, either via CSV or API, and we take care of the rest! Our solution will extract information such as equipment specifications, maintenance reports, Single Line Diagram, thermographic images etc., to create a digital twin within minutes and then provides comprehensive health status of your plant from day 1.

MAXIMISE PERFORMANCE BY 10%

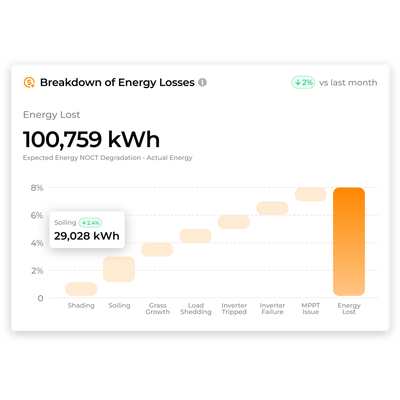

Uncover theHidden Losses

Our One-Time Diagnostics solution identifies root-causes of all your losses, and predicts equipment failures in the future. It provides you with a report that includes a waterfall diagram, current and projected losses and suggests prioritised actions to the user.