TWAICE Model Base

Chemistry specific model based on TWAICE’S database

- Compare li-ion battery chemistries & formats

- Immediately integrate into your system simulation environment

- Get immediate access to your model

TWAICE Model Customized Base

Base Model enriched with customers own cell-data (e.g. from cell data sheet)

- Fast access to aging insights

- Use existing measurement data to optimize costs

- Model delivery within 2 weeks

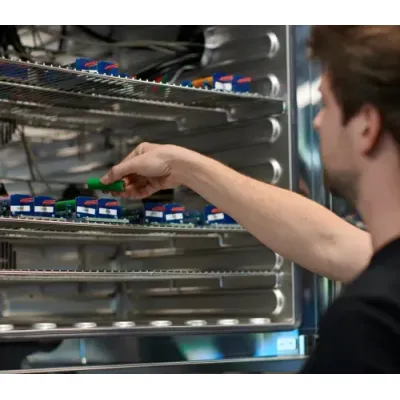

TWAICE Model Premium

Cell-specific model based on in-house measurements from TWAICE lab

- Best-in-class simulation model for your specific cell

- Custom design of measurements & flexible adaption to modeling approaches

- Advanced simulation functionalities e.g., OCV aging and modeling of degradation modes