- Home

- Companies

- ENEXSA GmbH

- Software

- Enexsa - Reciprocating Engine Library ...

Enexsa - Reciprocating Engine Library for Gas and Diesel Engines

The ENEXSA Reciprocating Engine Library is designed for the use within EBSILON®Professional Component 153 (Reciprocating Engine). This component is designed to represent large gas or diesel engines with heat integration. The performance data are supplied and approved by the respective OEM.

The combination of thermal performance data and detailed information about the control schemes for temperature and flow of the different cooling cycles within the gas engine is important for the simulation of a modern highly-integrated CHP plant. It is possible to calculate the load-dependent amount of available waste heat from the engine, which can be optimally utilized in the connected systems. This approach allows the user to produce an exact digital twin of the plant which is valid over the entire operating range.

In order to reach maximum fuel efficiency, modern engine-based CHP plants aim at maximum integration of the waste heat available from the engine. To describe the heat available from the engine, up to six heat sources can be defined, and the utilization of this heat is controlled in four different heat rejection groups. Multiple options for control schemes for flow and temperature of the different cooling cycles allow for accurate representation of the energy released from the engine, not only in terms of duty, but also in terms of flow and temperature. The latter is important for the correct simulation of the heat utilization, since these parameters may become limiting under specific operating conditions.

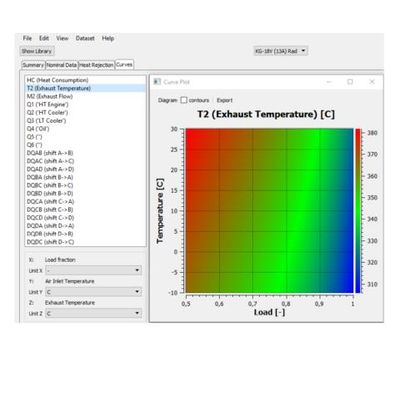

The ENEXSA Reciprocating Engine Library data sets describe power, heat consumption, exhaust temperature, exhaust flow and various heat sources (HT, LT, Oil) with respective shift of heat as a function of temperature and load. The correlations are given as two-dimensional matrices. The sample screen shot shows the correlation of exhaust temperature and engine load fraction with inlet temperature as the secondary parameter.