- Home

- Companies

- Spotfire, by Cloud Software Group, Inc.

- Software

- Spotfire - Spotfire Predictive ...

Spotfire - Spotfire Predictive Analytics Software for Predictive Maintenance

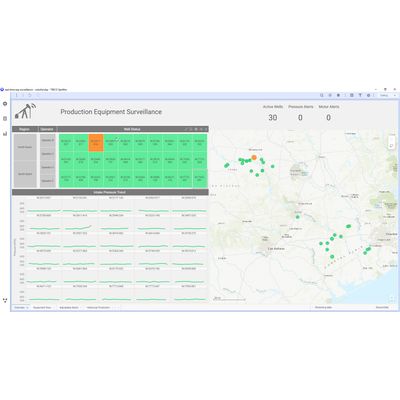

TIBCO's Spotfire platform provides predictive analytics solutions that allow businesses to monitor equipment and performance, improving business outcomes by reducing equipment failure and resource costs. By leveraging embedded IoT sensors, Spotfire analyzes data to predict breakdowns, allowing for timely maintenance scheduling that prevents costly production stops or slowdowns. Proactive maintenance capability enhances asset reliability, with operations teams receiving alerts based on set parameters, enabling corrective actions. The platform also integrates streaming IoT data with data science models and governed reference data to identify potential failures and defects, generating predictive alerts and automated responses. Spotfire's predictive maintenance tool includes a parametric failure model with Weibull curve distribution, supporting confident prediction of maintenance needs. It is a critical component for manufacturing intelligence in the era of Industry 4.0 and the IoT, enhancing uptime and customer satisfaction.

Monitor equipment and performance for better business outcomes

Reduce equipment failure and resource costs by predicting breakdown and managing resources

Predictive maintenance allows you to schedule interventions that avoid costly stops or slowdowns in production. With Spotfire® predictive analytics, you can set parameters to monitor equipment and devices using embedded IoT sensors.

Gain insights into all your resources and assets

Proactive maintenance for better reliability

Anticipate equipment failures based on set parameters and factors in Spotfire. Once flagged, operations teams are able to take corrective action and prevent future failures by scheduling maintenance.

Manufacturing and retail

Keep your customers happy with always on resources. Reduce breakdown occurrence and maximize asset uptime by improving asset reliability. Use streaming IoT data and data science models with governed reference data to identify potential process failures and production defects and generate predictive alerts and automated action.