- Home

- Companies

- Efficiency Scientific Instrument Co., ...

- Applications

- A Solution For Analyzing Graphite ...

A Solution For Analyzing Graphite Elements In New Energy Lithium-Ion Batteries ---- EDX8800G MAX - Metal

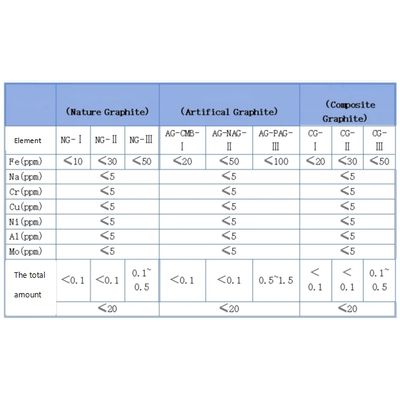

1. Background and Introduction Graphite is crucial for lithium - ion battery (LIB) anode, affecting energy density, cycling stability, and safety. But trace impurities like Fe, Ni, Cu, and magnetic particles can seriously degrade battery performance, leading to side reactions, electrolyte breakdown, and internal short - circuits. As the new energy sector grows, high - purity graphite demand in LIBs surges. Both natural and synthetic graphite need tight quality control (e.g., <1 ppm for critical metals). Traditional ICP - MS detection is slow, destructive, and costly. X - ray fluorescence (XRF) spectroscopy offers a fast, non - destructive, high - throughput alternative. This paper focuses on the EDX8800G MAX vertical XRF spectrometer's use in detecting impurities in graphite - based anode materials to meet industry standards. Regulations set technical limits for elemental content in different LIB graphite - based anodes, as follows.

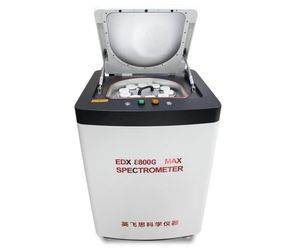

The EDX8800G MAX spectrometer, developed by ESI, is designed for high - precision material composition analysis. It is commonly used in third - party laboratories and other settings demanding accurate compositional insights. This spectrometer specializes in the qualitative and quantitative analysis of major, minor, and trace elements or compounds across a wide range of materials. Its applications span multiple industries:

Metals and Minerals: In alloy materials, precious metals, iron ore powder, non - ferrous metals and their powders, metallurgy, as well as metal and non - metal mineral resources. It enables rapid analysis of refractory materials, raw refractory materials, and helps in the quality control of minerals like titanium dioxide.

Industrial Minerals and Building Materials: It is used for analyzing gypsum, catalysts, ceramics, cement, lime, glass industry materials such as quartz, feldspar, and calcite. It also plays a role in the assessment of clay, rock wool, which are important in construction - related applications.

Other Specialized Materials: It is useful for rare - earth permanent magnets, petroleum products, and slag. By analyzing production raw materials and finished products, it ensures quality and composition compliance.

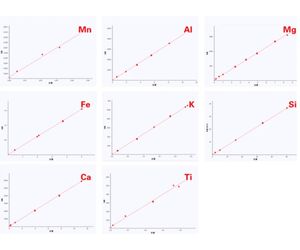

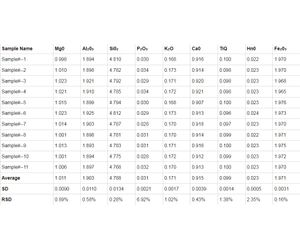

The EDX8800G Max is an instrument specifically designed to detect the content of elements such as Mg, Al, Si, P, K, Ca, Ti, Mn, and Fe in lithium batteries.

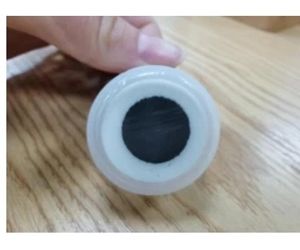

To prepare the sample, simply grind it finely using a pestle and mortar. Then, put the resulting powder into a sample cup with a special film for testing. Place the sample cup in the sample chamber of the EDX8800G Max analyzer for measurement.

3.1.1 Crush and grind the sample.

3.1.2 Put the ground sample into a sample cup with a special film.

3.1.3 Place the sample in the EDX8800G Max to prepare for testing.

The EDX8800G MAX vertical XRF spectrometer provides an efficient and reliable solution for detecting trace elements and magnetic impurities in graphite-based anode materials. Its high sensitivity, rapid analysis, and non-destructive nature make it ideal for quality control in LIB production. By ensuring ultra-low impurity levels, this technology supports the development of safer, higher-performance lithium-ion batteries, advancing the global transition to sustainable energy systems.