- Home

- Companies

- Beston Group Co., Ltd.

- Articles

- 3 Major Technological Breakthroughs in ...

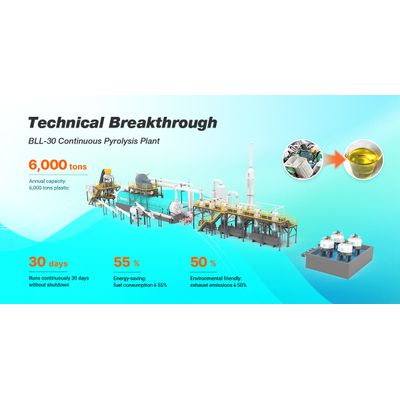

3 Major Technological Breakthroughs in Continuous Pyrolysis Equipment

The continuous pyrolysis equipment for plastic, tire, and oil sludge cracking has seen significant advancements in technology that offer improved efficiency, cost savings, and environmental benefits. Below are the three key technological breakthroughs that set this equipment apart:

1. Efficient Oil-Gas Condensation and Anti-Polymerization Technology

This technology uses a direct spray mixing method to quickly reduce the oil and gas temperatures, improving the condensation efficiency. By preventing the polymerization of olefin compounds, it avoids the blockage of oil-gas pipelines, which could lead to downtime and the need for maintenance. This breakthrough ensures that the continuous pyrolysis plant operates continuously for up to 30 days without interruptions, optimizing production cycles and reducing the risk of costly repairs and downtime.

2. Hot Flue Gas Recycling and Air Preheating Technology

The innovative flue gas recycling system utilizes high-temperature stainless steel fans to reintroduce 80% of the waste flue gas from the furnace back into the combustion chamber. This flue gas is then mixed with high-temperature air (1000-1300°C) provided by the burner, which is used to heat the reactor. Additionally, 20% of the exhaust gas is recovered and used to preheat the combustion air. Together, these two technologies achieve a 55% energy savings and reduce emissions by 50%, making the system more energy-efficient and environmentally friendly. This also simplifies the treatment of exhaust gases and cuts down on the investment needed for exhaust gas treatment systems.

3. Automatic Temperature Control Technology for the Main Furnace

This system employs a multi-medium automatic combustion valve group combined with heat recovery to regulate and control the temperature. It adapts automatically to different fuel conditions and adjusts the fuel-air mixture accordingly, maintaining a temperature precision of ±10°C. The high level of automation ensures easy operation and precise temperature control, greatly enhancing operational efficiency while simplifying the management of the pyrolysis process.

These three groundbreaking technologies combined offer a more energy-efficient, environmentally friendly, and cost-effective solution for the cracking of plastic, tire, and oil sludge. Not only do they ensure the continuous operation of the equipment, but they also contribute to reducing fuel consumption and emissions—addressing both operational costs and environmental compliance.