- Home

- Companies

- Henan Doing Environmental Protection ...

- Articles

- Harnessing the Potential of Pyrolysis: ...

Harnessing the Potential of Pyrolysis: A Guide to Processing Various Waste Materials

Pyrolysis is a transformative technology that can effectively process a wide range of waste materials, converting them into valuable products like fuel oil, carbon black, and gas. This article outlines the types of raw materials suitable for pyrolysis and describes the general process flow of a waste pyrolysis machine.

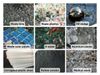

1. Types of Raw Materials for Pyrolysis

(1)Waste Rubber Tires:

Pyrolysis can handle various types of waste rubber tires, including steel wire tires, nylon tires, bicycle tires, and even rubber soles. This category also includes pure rubber cable skins and other rubber-based products. The process breaks down these materials into useful products, reducing environmental impact and recycling valuable resources.

(2)Waste Plastics:

A diverse array of plastics can be processed through pyrolysis. This includes polyethylene (PE) cable skins, polypropylene (PP), polystyrene (PS), acrylonitrile butadiene styrene (ABS), and other plastic waste. Pyrolysis can also handle pure plastic bags, medical plastic waste, and aluminum-plastic composites. The ability to process these materials aids in managing domestic and industrial plastic waste.

(3)Oil Sludge:

Pyrolysis is effective for treating various types of oil sludge, including dirty oil sludge, coal tar, drilling sludge, and oil-based shale. This process helps to recover valuable oils and reduce the volume of hazardous waste, making it an essential technology for managing oily waste.

(4) Special Raw Materials:

Beyond conventional waste, pyrolysis can address garbage, solid waste, and hazardous materials. This flexibility in processing enables the effective recovery of useful substances from challenging waste streams.

2. Pyrolysis Process Flow

The typical pyrolysis process involves several key stages:

(1)Feeding:

The raw materials are first fed into the pyrolysis reactor. The design of the feeding system varies depending on the type and form of the material to ensure efficient processing.

(2)Heating:

Once inside the reactor, the materials are subjected to high temperatures in an oxygen-free environment. This heating process decomposes the raw materials into oil and gas.

(3)Cooling:

The gas produced during pyrolysis is cooled and condensed into liquid fuel oil. This cooling system is crucial for recovering the valuable fuel from the gaseous byproducts.

(4)Exhaust Gas Recovery:

Non-condensable gases are collected and recycled. Often, these gases are used to heat the pyrolysis reactor, thereby reducing fuel consumption and increasing the overall efficiency of the process.

3. Pyrolysis offers significant environmental and economic benefits:

(1)Resource Recovery: By converting waste into valuable products, pyrolysis helps in resource recovery and reduces landfill use.

(2)Environmental Protection: The technology minimizes the environmental impact of waste disposal and contributes to cleaner waste management practices.

(3)Energy Production: Pyrolysis oil can be used as a substitute for conventional fuels, supporting sustainable energy solutions.

4. Custom Solutions and Expertise

At Henan Doing Company, we specialize in manufacturing and exporting pyrolysis machines tailored to various waste materials. Our experience in pyrolysis technology enables us to offer customized solutions that cater to specific material characteristics and operational requirements.

We invite you to inquire about our pyrolysis solutions. By sharing details about the waste materials you intend to process, we can provide tailored machine designs that optimize efficiency and output. Our one-stop service approach includes consultation, machine design, installation, and ongoing support, ensuring a smooth and effective implementation of your pyrolysis plant.