- Home

- Companies

- Beston Group Co., Ltd.

- Articles

- Is Pyrolysis a Continuous Process?

Is Pyrolysis a Continuous Process?

Pyrolysis is a thermal decomposition process that breaks down organic materials, such as plastic, rubber, and biomass, in the absence of oxygen. This process has gained significant attention for its potential in waste management and resource recovery, offering an effective way to convert waste into valuable products like fuel, gas, and biochar. A key question that often arises is whether pyrolysis is a continuous process. The answer depends on the type of pyrolysis system used.

Pyrolysis can be classified into two main types: batch pyrolysis and continuous pyrolysis. Both systems have their own operational mechanisms and are suited for different types of applications.

1. Batch Pyrolysis

Batch pyrolysis is a process in which a fixed amount of material is loaded into the reactor, heated to the desired temperature, and allowed to undergo thermal decomposition. After the process is completed, the system is cooled, and the products are removed before another batch of material is added.

This process is commonly used for smaller-scale pyrolysis plants or where the input materials vary in size and type. While batch pyrolysis offers flexibility, it can be less efficient compared to continuous pyrolysis because of the downtime between batches.

2. Continuous Pyrolysis

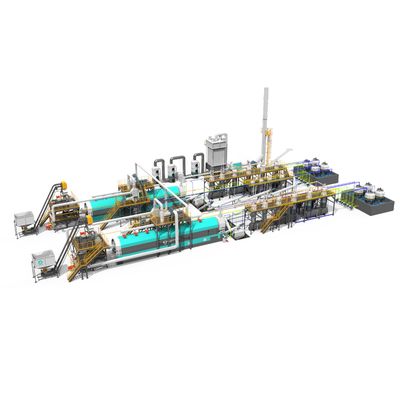

Continuous pyrolysis, on the other hand, is a process where materials are fed into the reactor continuously, and the products are removed as they are produced. This continuous pyrolysis plant operates without interruption, making it more efficient for large-scale operations. In continuous pyrolysis systems, the feedstock is added at a constant rate, and the products are separated and collected in real-time.

This type of pyrolysis is typically used in large-scale industrial applications where a steady supply of feedstock is available, and the process needs to run for extended periods. Continuous pyrolysis plants are ideal for applications such as plastic recycling, tire pyrolysis, and biomass conversion, where the demand for consistent output is high.

In summary, pyrolysis can be both a batch and a continuous process, depending on the system used. Batch pyrolysis is ideal for smaller-scale or variable operations, while continuous pyrolysis is better suited for large-scale, industrial applications where efficiency and consistency are critical. Continuous pyrolysis systems offer numerous benefits, including higher throughput, better product quality, and cost savings, making them the preferred choice for many businesses in the waste-to-energy and recycling industries. However, the decision to opt for continuous pyrolysis should be based on factors such as feedstock type, scale of operation, and available investment.