Biochar Machine Articles & Analysis: This-Year

9 articles found

Biochar, a carbon-rich material derived from biomass through thermal decomposition, has gained prominence as both a soil amendment and an industrial input. The utilization of biochar pyrolysis equipment allows for controlled production, ensuring consistent quality and scalability. Beyond agriculture, biochar exhibits multifaceted applications in industrial domains where its physical and chemical ...

The growing availability of modern biochar production machines makes this solution increasingly practical for farmers, businesses, and environmental projects worldwide. ...

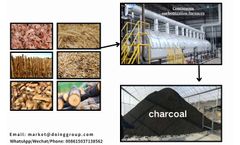

The best feedstock for biochar production depends on its availability, carbon content, and ease of processing. High-quality biochar raw materials generally share several common characteristics: high carbon content, suitable density, and a reasonable ash content. Biomass rich in lignin and cellulose is generally preferred because it produces high-quality, stable biochar with good porosity and ...

Transforming organic waste into a functional, high-value additive has become central to sustainable waste management and regenerative agriculture. Biochar production technologies have matured significantly, allowing for the controlled conversion of biomass into a carbon-rich material with wide-ranging applications. At the forefront of this evolution is the biomass pyrolysis plant for sale, an ...

Continuous biomass pyrolysis machine DOING biochar carbonization reactor is designed for continuous operation and can quickly process large amounts of biomass. ...

American BioCarbon, a leading innovator in sustainable products derived from sugarcane bagasse, was among a select group of esteemed U.S. and international leaders invited to contribute their insights at Economist Impact’s 3rd annual Sustainability Week: Countdown to COP28 conference. This pivotal climate change event, held in London and virtually earlier this week, convened 8,500 business ...

Biochar pyrolysis is a thermochemical process that involves heating biomass - materials such as wood, agricultural waste, or dedicated energy crops - in an oxygen - limited environment. As the biomass is heated to temperatures typically ranging from 300°C to 800°C, a series of complex chemical reactions occur. The biomass decomposes, releasing volatile gases like methane, hydrogen, and ...

Diversified Revenue Streams One of the most compelling reasons to invest in a biochar machine is the opportunity to create multiple revenue streams. ...

Biochar production has become an essential part of the sustainable waste management and renewable energy sectors. ...