Refine by

Carbonization Articles & Analysis: Older

1,963 articles found

This method produces high-quality charcoal while capturing byproducts like combustible gases, which can be reused to power the machinery itself. Carbon Sequestration Potential Charcoal production from forest waste contributes to carbon sequestration, a critical factor in combating climate change. The carbon stored within the biomass is ...

Instead of incinerating or landfilling the rice husks, which can incur significant disposal costs, carbonization through a rice husk carbonizer offers a sustainable alternative. ...

For consulting engineers tasked with planning, designing and supervising construction projects, today’s zero-emission high-voltage electrode boilers offer advantages over traditional fossil-fuel burning models. Used for centralized heating, power plants, swing-load balancing and fuel boiler replacements, they can match the capacity (up to 65 MW) and output (270,000 lb of steam per hour) of ...

Collection of Products: As the plastic undergoes pyrolysis, it will produce a range of products including fuel oil, syngas, and solid residues like carbon black. Collect the fuel oil from the condenser attached to the pyrolysis reactor. ...

Lower dependency on chemical inputs aligns with sustainable farming practices, potentially qualifying farms for tax credits or subsidies. Carbon Sequestration: One of the most significant advantages of biochar is its ability to sequester carbon. By locking carbon into a stable form, biochar helps offset the emissions generated by livestock ...

Charcoal is made by heating biomass waste such as wood and fruit shells in an oxygen-deficient or low-oxygen environment. This process is called carbonization. The carbonization process removes moisture, volatile substances and other impurities from the wood, leaving behind a substance that is almost pure carbon, namely charcoal. ...

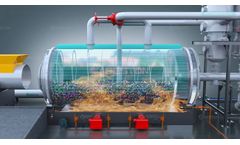

The whole set of continuous carbonization furnace converts biomass into charcoal by controlling the temperature, pressure and gas of the carbonized material. The whole set of processing technology of the continuous carbonization furnace includes four processes: drying, high-temperature cracking carbonization and cooling. 1. ...

The classification of carbon steel is usually based on its carbon content, divided into mild steel, medium carbon steel, high carbon steel, they are different in hardness, strength, processing and performance. ...

This digestion process produces biogas—a mixture of methane and carbon dioxide. Capturing this energy, similar to natural gas, powers operations and reduces reliance on fossil fuels, while also mitigating greenhouse gas emissions. ...

This process not only reduces waste but also yields a product that has significant benefits in agriculture, carbon sequestration, and waste management. Below is an overview of the key steps involved in the operation of biochar production equipment. 1. ...

Pipelines transporting natural gas are made of carbon steel, a strong and durable steel alloy. Constant wear and tear, however, diminishes the integrity of the pipeline. ...

Types of Carbon Steel Carbon steel, as you can probably gather from the title of this article, comes in forms graded by their specific carbon content. Low-carbon steel is that which contains less than 0.25 percent of carbon; medium-carbon steel contains 0.25 percent to 0.55 percent ...

Furthermore, by optimizing heat management, the reactor can minimize the release of pollutants such as carbon monoxide, volatile organic compounds (VOCs), and other harmful gases that may form during incomplete combustion or inefficient pyrolysis. By operating with a higher thermal efficiency, pyrolysis plants can reduce their carbon footprint, contributing to ...

Pyrolysis Reactor The core component of a continuous pyrolysis machine: Material: Typically made of carbon steel or stainless steel, resistant to high temperatures and corrosive environments. ...

Having complete a site energy audit at the head office and manufacturing facility, a number of energy efficient recommendations were suggested to the board. In a drive to reduce carbon emissions and increase energy resilience a 945kWp Solar Photovoltaic system was the preferred solution. ...

Electric vehicles (EVs) are rapidly becoming more popular as consumers and governments worldwide recognize the numerous benefits they offer. From reducing carbon emissions to saving money on fuel, EVs provide a cleaner, more sustainable, and cost-effective alternative to traditional gasoline-powered cars. ...

In indirect calorimetry, the individual breathes into a device that measures the volume of oxygen consumed (VO2) and the volume of carbon dioxide produced (VCO2). Oxygen is used by the body for metabolic processes that generate energy, while carbon dioxide is produced as a byproduct of these processes. ...

However, some formulations may produce slightly higher emissions of carbon monoxide (CO) or particulate matter (PM) than standard diesel, especially if the oil contains impurities. ...

In the textile industry, energy costs and environmental concerns are significant challenges. Sartex, an industrial group specialising in the manufacture of jeans, opted for a cogeneration solution to meet the challenges of rising energy costs and environmental pressures. Sartex chose Clarke Energy to design, supply and install its CHP plant to solve these problems efficiently. This installation ...

A continuous pyrolysis plant is designed to streamline the conversion of waste materials, such as plastics and tires, into valuable resources like fuel oil, carbon black, and syngas. Understanding its operating cycle time is essential for businesses and operators to achieve efficiency, maximize output, and make informed decisions about processing volumes, energy usage, and ...