Charcoal Briquette Extruder Machine Articles & Analysis

44 articles found

Barbecuing is a popular outdoor activity, and barbecue charcoal is an essential fuel for both outdoor grilling and catering. So, how to make high-quality barbecue charcoal? While the process isn't complicated, it does require certain equipment and skills. BBQ charcoal is typically made by carbonizing wood at high temperatures. This process removes moisture and volatile substances from the wood, ...

As an environmentally friendly fuel, charcoal plays an important role in agricultural improvement, energy utilization and environmental protection. If you are considering entering the field of charcoal production, understanding the professional machine required is the first step to success. Several types of machine are usually needed to produce charcoal. These include raw material preparation ...

To make briquettes, you typically use a briquette machine, also known as a briquetting machine. This equipment is designed to compress various raw materials into solid briquettes, which can be used as fuel, in construction, or in other applications. There are several types of briquette machines, each suited to different materials and applications: Types of Briquette Machines Hydraulic Briquette ...

Charcoal, a versatile and widely used fuel, has been a staple for centuries. From cooking to industrial applications, its demand remains consistent. However, the raw form of charcoal often presents challenges in terms of handling, storage, and efficiency. This is where a charcoal briquetting machine comes into play. By transforming loose charcoal into compact, uniform briquettes, this machinery ...

Investing in a high-quality charcoal making machine can be a profitable venture, given the rising demand for sustainable and eco-friendly energy sources. However, to maximize returns, it is crucial to develop a comprehensive investment strategy. This strategy should encompass market analysis, cost assessment, technology evaluation, and risk management. Below, we explore these elements in detail ...

At its core, the line revolves around specialized equipment engineered to handle the intricacies of charcoal production efficiently and sustainably. Components of a Charcoal Machine A charcoal machine is the centerpiece of the production line, embodying sophisticated engineering to transform raw materials into ...

Looking for the very best charcoal briquette machine for your facility? Of course, you're seeking a charcoal-making machine that converts biomass into charcoal utilizing the most innovative carbonization technique (also called pyrolysis technology). Is, however, all you're seeking for? Just what is a Charcoal Making Machine? A charcoal manufacturing plant is a device that converts biomass waste ...

The two main varieties of charcoal making machine: batch type and continuous type. Both of them are easy to operate and install. They can be completely sealed to avoid dust from flying across the production area. They can process different materials and are utilized to create both dry and wet charcoal. As oil storage is becoming scarce worldwide, charcoal is a great fuel alternative. Charcoal is ...

This charcoal plant was installed in Russia last year to make sawdust charcoal. The Russian customer then uses the charcoal powder to make fast-burning charcoal briquettes. This continuous charcoal machine can realize the large-scale production of charcoal, and its processing capacity per hour is between 800kg and 3t (based on different models). Therefore, this charcoal carbonizer is very ...

A charcoal making machine uses pyrolyzing strategy to turn biomass waste materials into charcoal. The charcoal-making process requires an oxygen-free atmosphere and extremely high temperature. This machine needs raw materials like biomass, such as palm shell, sugarcane bagasse, peanut shell, olive shell, sawdust, coconut shell, rice husk, bamboo, and wood, sorted MSW, and sewage sludge. The ...

The barbecue charcoal production line mainly processes various types of charcoal balls. The BBQ charcoal briquettes processing plant can produce barbecue charcoal of various specifications and sizes. The industry’s barbecue charcoal production line is an automated BBQ briquettes processing line independently designed by the Shuliy factory. The production line mainly includes a continuous ...

Industrial charcoal processing equipment is essential for the modernization of charcoal production. Different specifications of charcoal production lines and charcoal processing solutions have improved production efficiency for thousands of charcoal processors and created considerable benefits. The charcoal production line is a general term for a series of charcoal and coal processing equipment. ...

Biomass charcoal briquette machine has a wide usage from agriculture to industry. Biomass briquette is a way for recycling the waste and get value from them. In agriculture Agriculture has a lot of waste every year. These waste include agricultural and forestry by-products and processing residues, energy crops, and organic waste such as human and animal waste, etc. Biomass energy is the only ...

So, what is the price of an industrial charcoal briquettes machine in the Philippines? Before purchasing charcoal briquettes machine, charcoal factories at home and abroad generally have a full understanding of the working principle, accessories, price, freight, and other issues ...

1, charcoal production machine equipment: to choose and buy a good charcoal briquette production machine equipment, quality, reasonable design of charcoal machine equipment to produce a good charcoal. 2. Raw materials: raw materials with high carbon content can produce carbon with high calorific value, better burning resistance, good market response and high price. 3, drying: to crush the raw ...

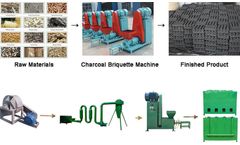

Charcoal briquette machine is the main equipment to make rodlike solid fuel under high pressure and high temperature by using wood, rice husk, peanut husk, plant straw, and other materials containing carbon wood. Machine-made charcoal has the advantages of high density, small volume, good flammability, smoke-free, tasteless, non-toxic, etc. It’s widely used in heating and BBQ market. In the ...

Charcoal briquette machine is an important machinery for the complete mechanism charcoal briquette production line. In production, it can effectively use agricultural and forestry wastes to produce mechanism charcoal and achieve energy-saving and environmentally friendly production. Therefore, it is chosen by the majority of users in the market, and the users who invest in the charcoal production ...

Charcoal making machine is accompanied by the widespread use of briquette and people increasingly demanding the environment, briquette press machine with briquette has been widely developed. Briquette press machine is widely used, can be a variety of pulverized coal (coking coal, lignite, coal, anthracite, etc.), slag, dry powder, slag, and other powder material fully pressed. Briquette press ...

Building a biomass charcoal briquette plant will help to reduce other fuel costs and make extra value from the biofuel briquette. Charcoal briquette machine is the indispensable equipment in the charcoal briquette production line. Why Make The Charcoal Briquette Plant For Biomass Waste Among the world’s major energy components, biomass energy is now one of the most rapidly growing energy ...

Charcoal briquette machine is the main equipment to make rodlike solid fuel under high pressure and high temperature by using wood, rice husk, peanut husk, plant straw, and other materials containing carbon wood. Machine-made charcoal has the advantages of high density, small volume, good flammability, smoke-free, tasteless, non-toxic, etc. It’s widely used in heating, BBQ market. In the ...