Refine by

Condition Assessment Articles & Analysis

66 articles found

Oil sludge, a byproduct of the petroleum industry, is a challenging waste material that requires efficient disposal or treatment. One promising method for processing oil sludge is oil sludge pyrolysis, a thermal decomposition process that breaks down complex hydrocarbons into useful products like oil, gas, and solid residues. However, one crucial factor that significantly affects the efficiency ...

The Impact of Seasonal Fluctuations on Crusher Plant Pricing Seasonal fluctuations in crusher plant pricing are influenced by several factors, including demand, supply, and external market conditions. During peak construction seasons, such as spring and summer, the demand for crusher plants tends to surge as construction projects ramp up. ...

Whether they are used in steel mills, shipyards, power plants, or manufacturing workshops, these cranes are constantly exposed to demanding working conditions that can lead to fatigue and wear over time. Ensuring the structural and mechanical integrity of these cranes is paramount for operational safety, equipment longevity, and cost-efficiency.This article explores the ...

When abnormal voltage or frequency (such as high or low voltage, or frequency deviations from normal range) is detected, the device assesses that the system may be in an islanding state and issues a protective signal. Although energy meters do not directly participate in anti-islanding protection, the voltage and frequency data they provide are crucial for ...

Employ preventive maintenance techniques like condition monitoring and predictive maintenance. 4. Quality Maintenance Objective: Ensure equipment consistently produces high-quality products. ...

Centrifugal pumps are widely used in the Industry. Pumps are one of the major contributors to energy consumption and plant breakdown occurrences. Pump operators usually face the following two challenges with centrifugal pumps: Poor Efficiency Poor Reliability The solution to the above two problems is simple – Operate the pumps at or near their best efficiency point. Even though this ...

Cost Savings: Implementing ESA as part of a predictive maintenance strategy can lead to cost savings by reducing the need for emergency repairs, extending equipment lifespan, and optimizing maintenance schedules based on actual asset condition. Continuous Improvement: Historical data analysis drives continuous improvement in maintenance strategies, refining predictive models for ...

Client: Frontier Subsea for Hibernia Management and Development Corporation Status: Completed Pennecon Hydraulic Systems (“PHS”) has a long history of preforming extensive mechanical equipment rebuilds on behalf of our clients and various Original Equipment Manufacturers (“OEMs”). For a significant amount of equipment in use in Newfoundland and Labrador offshore oil ...

Year: 2022 Running Gear: 2 vertical shaft Francis turbines with synchronous generators Scope: Replacement of control system, excitation, and governors Set in a resort town in the mountains of North Carolina, this hydroelectric project was originally constructed in 1925-1926 by a private developer. Its primary purpose was to create a beautiful lake as the centerpiece of a huge resort/real ...

Year: 2021 Running Gear: 2 Vertical shaft Francis turbines with synchronous generators Scope: Replacement of control system, exciters, and HPUs Originally part of a large cotton mill complex in North Carolina dating back to the 1800s, this 1 MW hydropower plant stayed in operation into the 2000s, longer than the rest of the declining mill town. The cotton mill itself finally shut down in ...

Year: 2018 Running Gear: 2 Vertical shaft Francis turbines with synchronous generators Scope: Replacement of control system and exciters This hydroelectric plant is located in central MA on a highly developed river, with multiple hydro plants operating both upstream and downstream of the project. Originally constructed in 1918 by a local manufacturing company, the project today consists of ...

Background:Soil sensors have become an important tool in precision agriculture, enabling farmers to monitor soil conditions and make informed decisions about plant growth and management. However, proper interpretation of soil sensor readings is essential to ensure accurate and effective decision making. This paper explores the importance of understanding soil sensor data and how it can be ...

ByJXCT

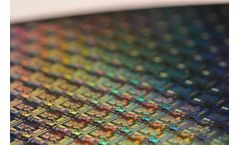

Semiconductors are the fundamental components of modern electronic goods. Cleanliness is crucial inside of a semiconductor fabrication facility, considering the scale of the working surfaces (nanometers). Contaminants of all types can result in defects, leading manufacturers to implement extremely strict and precise production control procedures with high reproducibility, especially during one ...

In the previous two posts in this series, we’ve looked at the hidden risks that make managing critical power facilities so challenging. We’ve also seen how digitalizing electrical power distribution networks trends mean you no longer have to ‘work blind.’ Connected smart devices sharing data with cloud or facility-based software and mobile apps help shine a bright light on ...

Electric vehicle recalls have accelerated as the risk of battery thermal runaway due to faults and failures remains a major pain point in the eMobility industry. General Motors recently took a $1.8 billion hit for battery warranty and replacement costs for the Chevrolet Bolt, according to CNBC, and it is not the only major OEM challenged by battery malfunction. While thermal runaway in electric ...

In my previous post in my series, I covered the importance of continuous monitoring of electrical equipment to prevent fires and equipment failures – not just to minimize the damage they cause once they’ve occurred. In this post, I’ll be discussing how those monitoring capabilities are getting built “natively” into today’s circuit breakers and electrical panels ...

US Defense Manufacturer uses VPVision to monitor and optimize production process By replacing liquefied N2 by instrument air, a US defense manufacturer has a savings potential of nearly $6.5 M USD over the 20-year lifespan of one manufacturing plant, on a $500 K investment. As this company owns several plants, their savings are a multitude. The manufacturer uses VPVision to ...

Most electric motors are equipped with anti-friction, grease-lubricated rolling-element bearings. These bearings are predisposed to fail along with your equipment if they are not lubricated properly—in fact, bearing troubles account for 50 to 65 percent of all-electric motor failures. The most common lubricant-related failures include improper lubricant selection and over-and ...

This data, when processed, translates into several benefits such as the possibility of carrying out predictive maintenance to prevent unscheduled machine downtime. By being able to monitor the condition and performance of the machine almost instantly, detect production failures and analyse their possible causes, downtime is reduced.In addition, production is maximised as, by ...

Why You Need to Implement a Condition-Based Monitoring Process Last week, we talked about the importance of investing in tools and technology, but equally as important would be the process that you use in your facility. There are a lot of facilities that don’t really have much of a process but instead approach with the old-fashioned way – they either go with the flow and make ...