Refine by

Condition Monitor Articles & Analysis

53 articles found

Optimizing Feedstock Handling: Effective moisture control in the handling and storage of oil sludge can prevent excess water from entering the system. This includes monitoring storage conditions and using drying techniques as needed. Blending with Low-Moisture Materials: In some cases, oil sludge can be mixed with drier materials to reduce the overall moisture ...

The Impact of Seasonal Fluctuations on Crusher Plant Pricing Seasonal fluctuations in crusher plant pricing are influenced by several factors, including demand, supply, and external market conditions. During peak construction seasons, such as spring and summer, the demand for crusher plants tends to surge as construction projects ramp up. ...

Whether they are used in steel mills, shipyards, power plants, or manufacturing workshops, these cranes are constantly exposed to demanding working conditions that can lead to fatigue and wear over time. Ensuring the structural and mechanical integrity of these cranes is paramount for operational safety, equipment longevity, and cost-efficiency.This article explores the ...

Employ preventive maintenance techniques like condition monitoring and predictive maintenance. 4. Quality Maintenance Objective: Ensure equipment consistently produces high-quality products. ...

Centrifugal pumps are widely used in the Industry. Pumps are one of the major contributors to energy consumption and plant breakdown occurrences. Pump operators usually face the following two challenges with centrifugal pumps: Poor Efficiency Poor Reliability The solution to the above two problems is simple – Operate the pumps at or near their best efficiency point. Even though this ...

Unplanned downtime or late fault detection in these motors can lead to following losses for the factory: Loss in production High energy consumption High capex investments due to reduced asset life Higher maintenance cost due to its unplanned nature Vibration, Ultrasound, Thermography, Electrical Signature Analysis (ESA) and Motor Current Signature Analysis (MCSA) are some common ...

Other features include: Automatic pond level control Generator and electrical protection Machine condition monitoring Effective alarming and push notifications The new PHT controls also use fiber optic communication and coordination between the powerhouse, dam, and operations center. ...

PHT provided a new control and automation system for the plant, including new Power-Tronics exciters, and additional instrumentation and machine condition monitoring. Like most retrofits of older equipment, PHT installed new water level sensors, RTD temperature sensors on the stator, bearings and oil loops, added RPM and vibration sensors, oils level sensors, and ...

In 2018, PHT supplied a new control and automation system, new exciters, and some additional instrumentation and machine condition monitoring. The new PHT controls now provide automatic starting, automatic pond level control and unit dispatch, and better monitoring and protection. ...

Background:Soil sensors have become an important tool in precision agriculture, enabling farmers to monitor soil conditions and make informed decisions about plant growth and management. ...

ByJXCT

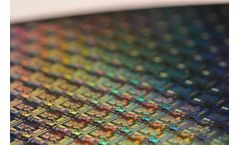

Semiconductors are the fundamental components of modern electronic goods. Cleanliness is crucial inside of a semiconductor fabrication facility, considering the scale of the working surfaces (nanometers). Contaminants of all types can result in defects, leading manufacturers to implement extremely strict and precise production control procedures with high reproducibility, especially during one ...

In the previous two posts in this series, we’ve looked at the hidden risks that make managing critical power facilities so challenging. We’ve also seen how digitalizing electrical power distribution networks trends mean you no longer have to ‘work blind.’ Connected smart devices sharing data with cloud or facility-based software and mobile apps help shine a bright light on ...

EVE-Ai™ Fleet Analytics is a fleet management software that anticipates battery faults and failures up to 3 months in advance. It accurately monitors battery State of Health (SOH) and State of Charge (SOC) of historical and real time data to send battery failure alerts, thereby drastically decreasing the need for EV recalls and ensuring battery safety. ...

In my previous post in my series, I covered the importance of continuous monitoring of electrical equipment to prevent fires and equipment failures – not just to minimize the damage they cause once they’ve occurred. In this post, I’ll be discussing how those monitoring capabilities are getting built “natively” into today’s circuit breakers and electrical panels ...

To check how much electric power is used to make test instrument grade dry air. To monitor the condition of the compressed air system, to make sure everything is running according to their specifications. ...

Most electric motors are equipped with anti-friction, grease-lubricated rolling-element bearings. These bearings are predisposed to fail along with your equipment if they are not lubricated properly—in fact, bearing troubles account for 50 to 65 percent of all-electric motor failures. The most common lubricant-related failures include improper lubricant selection and over-and ...

This data, when processed, translates into several benefits such as the possibility of carrying out predictive maintenance to prevent unscheduled machine downtime. By being able to monitor the condition and performance of the machine almost instantly, detect production failures and analyse their possible causes, downtime is reduced.In addition, production is ...

Why You Need to Implement a Condition-Based Monitoring Process Last week, we talked about the importance of investing in tools and technology, but equally as important would be the process that you use in your facility. ...

It’s powering the vast and ever-growing array of sensors and monitoring equipment used in the ocean across all industries. To spotlight just one brand-new use case, storage of captured carbon deep below the seafloor will require both mobile and fixed monitoring equipment to ensure the integrity of the reservoir. ...

In our last blog we provided a link to a case study on our website focussing on reducing the cost of condition monitoring programs, in particular oil analysis. ...