Heat Exchanger For Food Processing Articles & Analysis

16 articles found

The coconut tree (Cocos nucifera) is one of the world’s most versatile and valuable plant species. Capable of producing food, fuel, cosmetics, building materials, growing media and cosmetic compounds, it’s no wonder that in the Philippines, the coconut is known as the Tree of Life. The global market for coconut products is predicted to reach $53.4 billion by 2033, thanks to annual ...

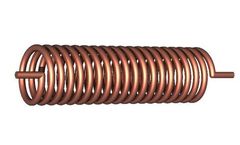

As we continue to innovate and adopt cleaner energy technology, renewable energy technologies are increasingly vital in our quest for sustainable and efficient energy solutions. Among these technologies, coil heat exchangers play a crucial role in enhancing the performance and efficiency of systems like geothermal heat pumps (GHPs) and solar thermal ...

As we continue to innovate and adopt cleaner energy technology, renewable energy technologies are increasingly vital in our quest for sustainable and efficient energy solutions. Among these technologies, coil heat exchangers play a crucial role in enhancing the performance and efficiency of systems like geothermal heat pumps (GHPs) and solar thermal systems. ...

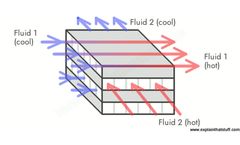

All but the most basic heat exchangers are created to a bespoke brief, designed to take into account the material/s being heated or cooled, the heating or cooling medium, the amount of product being processed, product velocity, risk of fouling and a host of other factors. ...

Econotherm GW 1200 finned to finned pipe heat exchanger. 1.2MW process water heater (Genset). Remote location: chosen for high reliability, no single point of failure, low fouling,easy cleaning and low maintenance, small footprint and weight ...

Depending on the flow form of the drying medium, the number of layers of the conveyor belt, and the temperature of the heating medium, the belt dryer can be divided into different types. According to the flow form of the drying medium, it can be divided into a through-flow belt type and a horizontal airflow belt type. According to the number of conveyor belt layers, it can be divided into ...

Retain more process fluids, save time and budget on maintenance, increase heat transfer efficiency by up to 50%, and integrate into your existing system, or upgrade to a new skid-mounted heater exchange ...

While heat treatment is important in ensuring the safety of apple juice through pasteurisation or sterilisation, for some products heat plays an important role in the production process itself. The physical and chemical properties must be considered when they are juiced and processed. Sugar content is typically around 11%, while dry matters vary between 13 and 20 % depending on variety and ...

Heat exchangers which employ heat recovery or regeneration should not be confused with ‘regenerative heat exchangers,’ which are a specific type of heat exchanger. What we mean by heat regeneration at HRS is the recovery of as much surplus heat (or cooling capacity) as possible after the primary function of the heat exchanger has been performed. This can then be reused to either ...

In every situation where a heat exchanger is required, the combination of products and service fluids, application, temperature and other variables will be different. Understanding these properties ensures the correct heat exchanger is supplied. For example, high fouling materials may require a scraped-surface unit. Having ...

Ensuring product safety is the number one priority for any producer of pharmaceutical products, and a key aspect of this is avoiding contamination during production. Design and construction plays a key role in achieving this, and the heat exchangers used for processes such as pasteurisation and sterilisation are no exception. There are three main elements to preventing contamination occurring in ...

OVERVIEW A food processing facility installed a new Regenerative Thermal Oxidizer (RTO) for odor control from its roasting operation. ...

The Situation A California refinery produces xylene for use as commercial product and a precursor for petrochemical manufacturing. A primary component to the production of xylene is the isolation and purification of the chemical from a complex mixture of petroleum hydrocarbons. Steam based heat exchangers are used to process the xylene. Inherent to the design and rough duty heat exchangers face ...

The deposition of material on heat transfer surfaces is called fouling which significantly impacts on the thermal and mechanical performance of heat exchangers. Fouling increases the overall thermal resistance and lowers the overall heat transfer coefficient of heat exchangers as well as impeding fluid flow, accelerating corrosion and increasing pressure drop across the heat exchanger. The ...

A process for converting Compressed Natural Gas (CNG) to Liquefied Natural Gas (LNG) is modelled thermodynamically and effects of design and operating parameters on exergy destruction and performance of the process are studied. Results show that CNG pressure, pressure after Joule?Thomson valve, and temperature of CNG after heat exchanger of refrigerating system have significant effects on optimum ...

Overview Emission control and the operating costs associated with meeting environmental regulations were nothing new for the Coated Products Division of Brady Corp. The company has been manufacturing coated films for nearly 60 years, demonstrating over that time a commitment to pollution prevention and emission reduction programs. But these considerations were magnified when the Milwaukee ...