Predictive And Preventive Maintenance Articles & Analysis

38 articles found

As global emphasis on energy efficiency intensifies, advancements in pyrolysis technology have shifted toward optimizing heat utilization and minimizing energy loss. Central to this evolution is the refinement of continuous pyrolysis plant design, which now integrates cutting-edge reactor engineering to enhance thermal performance, throughput, and system longevity. Evolution of Reactor ...

Case Example: Predictive Maintenance in a Steel MillIn a steel manufacturing facility, a 40-ton overhead crane operates continuously across three shifts. ...

By minimizing separate communication wiring and leveraging standardized plug‑and‑play interfaces, smart connectors reduce installation complexity and unlock advanced predictive maintenance capabilities. 6. Torque Control and Maintenance Protocols Even the best components fail under improper assembly. ...

We’ll also introduce RICHYE, a lithium battery specialist whose advanced solutions power forward-thinking material handling fleets. 1. From Reactive Maintenance to Predictive Insights Lead-Acid’s Maintenance Burden Maintaining lead-acid forklift batteries demands daily watering, periodic equalization charges, and the constant ...

Maintaining these machines in top condition is crucial to prevent costly downtime and ensure operational efficiency. Predictive maintenance is an advanced approach that helps monitor the health of mobile stone crushers and predict when maintenance should be performed. ...

By keeping parameters within optimal working thresholds, the system mitigates risks of overloading, overheating, or premature wear. Diagnostic Features to Prevent Malfunctions Modern concrete trailer pumps are equipped with self-diagnostic capabilities, allowing for early fault detection and predictive maintenance. ...

Introduction Syngas, or synthesis gas, is a vital component in various industrial processes, serving as a fuel source and a raw material for chemical synthesis. It is primarily used in power generation, chemical production, and fuel manufacturing. Accurate measurement of syngas is critical to ensuring efficiency, safety, and compliance with industry standards. This article explores the ...

Establish standardized procedures and schedules. Planned Maintenance Objective: Prevent equipment failures and extend equipment life. Activities: Develop a proactive maintenance schedule using equipment history and performance data. Employ preventive maintenance techniques like condition monitoring and ...

Training Programs: Educating operators on machine operation, maintenance, and troubleshooting. Maintenance and Spare Parts Reliable after-sales service, including maintenance and spare parts availability, is essential for the sustained operation of biochar machines. Key considerations include: Regular Maintenance Programs: ...

Induction motors are the leading drive systems used in Industrial setups. Induction motors are used in wide load applications from low voltage to high voltage. Unplanned downtime or late fault detection in these motors can lead to following losses for the factory: Loss in production High energy consumption High capex investments due to reduced asset life Higher maintenance cost due to its ...

As the core component of modern energy management systems, smart energy meters have already brought significant changes and efficiency improvements in many aspects. However, with the rapid development of technology and continuous innovation, smart energy meters may potentially have disruptive functionalities in the future, which will completely change our understanding of electricity usage and ...

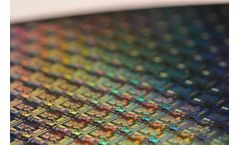

The semiconductor fabrication industry, which is vital to the modern digital era, hinges significantly on the precision and purity of gasses used in its manufacturing processes. Ultra high purity gas mixing plays a pivotal role in ensuring the quality and performance of semiconductors. This article delves into the intricacies of ultra high purity gas mixing. It explores its importance, ...

Predictive maintenance requires monitoring The demand for electrolysers is growing by leaps and bounds. They are needed all over the world to produce the hydrogen that is to replace fossil energy sources in numerous sectors of the economy. In view of the rising demand, manufacturing costs are expected to fall significantly in the medium term as industrial mass production progresses. Further cost ...

Semiconductors are the fundamental components of modern electronic goods. Cleanliness is crucial inside of a semiconductor fabrication facility, considering the scale of the working surfaces (nanometers). Contaminants of all types can result in defects, leading manufacturers to implement extremely strict and precise production control procedures with high reproducibility, especially during one ...

Carrying out a predictive maintenance plan is a smart way to avoid future costs, you know that. ...

Industrial facilities and manufacturers are especially keen to use predictive analytics to monitor heat and cooling equipment performance: they can automatically alert malfunctions, prevent errors or notify when it is time for maintenance. ...

Globally, every industry is accelerating decarbonization initiatives. Buildings and factories are becoming more electrified by replacing fossil-fuel-based heating and processes. As more renewable energy is progressively added to the power grid, the grid itself must take steps to decarbonize. The SF6 greenhouse gas currently has a unique use exemption in insulating medium-voltage (MV) electrical ...

Artificial Intelligence and machine learning can assist discoms to manage consumer grievances, theft and pilferage detection, predictive and preventive maintenance. Novel technologies such as peer-to-peer blockchain trading can make RE more accessible, concurrently providing a host of other benefits such as grid balancing and the provision of ...

But they are all doing so in the knowledge that no digitisation strategy can turn its back on data analytics.For example, by treating data in the right way, it is possible to create detailed reports on everything that happens in a factory or to establish Artificial Intelligence (AI) algorithms capable of reacting in real time to unforeseen production events and even predicting ...

Client Introduction & Business Requirements: Our client is a multinational beverages company offering over 500 brands across 200 countries and territories. They have a huge inventory of coolers which are deployed at their customer locations worldwide. These coolers need to be regularly serviced and assigned to the right location. They also need to be refurbished with stock on a periodic ...