Pyrolysis A Continuous Process Articles & Analysis: This-Year

23 articles found

Oil sludge, a byproduct of the petroleum industry, is a challenging waste material that requires efficient disposal or treatment. One promising method for processing oil sludge is oil sludge pyrolysis, a thermal decomposition process that breaks down complex hydrocarbons into useful products like oil, gas, and solid residues. However, one crucial factor that significantly affects the efficiency ...

What Is Pyrolysis Technology? Pyrolysis is a high-temperature, oxygen-free process that breaks down organic materials, such as plastics, biomass, and waste tires, into useful by-products like oil, gas, and char. ...

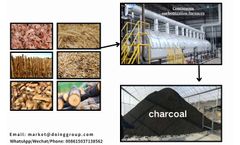

A charcoal maker machine converts biomass materials into high-quality charcoal through a high-temperature carbonization process. This process not only preserves the energy value of the raw materials but also significantly reduces the environmental pollution caused by direct incineration. ...

By incorporating specialized catalysts into the pyrolysis process, industrial operators can significantly improve oil yield, enhance product quality, and optimize energy efficiency. ...

Starting a small pyrolysis project can be an excellent way to generate profit with a relatively low investment. Pyrolysis, the process of converting organic materials like plastic, rubber, and biomass into valuable products such as fuel, carbon black, and gas, offers substantial financial opportunities for small-scale entrepreneurs. In this blog post, we'll explore how a small pyrolysis machine ...

However, the quality of the carbon black produced during tire pyrolysis can vary based on several factors, and understanding these influences is essential for maximizing the value of the process. ...

Continuous biomass pyrolysis machine DOING biochar carbonization reactor is designed for continuous operation and can quickly process large amounts of biomass. ...

The coconut industry is traditionally known for producing oil, water, milk, and coir, but there’s an often-overlooked byproduct with tremendous untapped value—the coconut shell. Once considered agricultural waste, coconut shells are now gaining recognition as a sustainable raw material for charcoal production, opening up new income streams and adding value across the supply chain. ...

The continuous pyrolysis equipment for plastic, tire, and oil sludge cracking has seen significant advancements in technology that offer improved efficiency, cost savings, and environmental benefits. ...

The equipment is equipped with an advanced automatic control system, which can realize accurate monitoring and regulation of the entire carbonization process. From the feeding of raw materials, the control of pyrolysis temperature to the collection of products, each link can be precisely operated through the intelligent system, which greatly improves the ...

The global environmental impact of industrial waste, particularly oil sludge, has become an increasingly pressing issue. The accumulation of oil-contaminated waste in landfills or open environments leads to severe soil contamination, adversely affecting soil quality, biodiversity, and agricultural productivity. However, advancements in pyrolysis technology offer a promising solution to alleviate ...

Pyrolysis reactors play a crucial role in the conversion of waste materials into useful products, such as bio-oil, syngas, and char. Whether you are considering investing in a pyrolysis reactor for industrial purposes or as part of a waste-to-energy project, it's essential to understand the key components of these reactors and the factors to consider when purchasing one. This blog will provide an ...

This heat causes the shells to decompose, releasing volatile gases and producing solid biochar.The by-products of the pyrolysis process, including gas and liquid oil, are captured and can be used to generate energy for the system or sold for other purposes. ...

To significantly reduce the amount of plastic waste entering the oceans, more advanced technologies need to be developed and implemented on a large scale. This is where pyrolysis technology steps in. How Pyrolysis Technology Works Pyrolysis is a thermochemical process that decomposes organic materials in the absence of oxygen, ...

Catalytic pyrolysis is a modified version of the traditional pyrolysis process. While traditional pyrolysis relies solely on heat to break down organic materials, catalytic pyrolysis introduces a catalyst into the reaction system. The catalyst acts as a facilitator, lowering the activation energy required for ...

A balanced approach is essential. Pyrolysis Time: The duration of the pyrolysis process also influences charcoal quality. ...

Biochar pyrolysis is a thermochemical process that involves heating biomass - materials such as wood, agricultural waste, or dedicated energy crops - in an oxygen - limited environment. ...

Diversified Revenue Streams One of the most compelling reasons to invest in a biochar machine is the opportunity to create multiple revenue streams. The core product of the pyrolysis process—biochar—has a range of applications across various industries, including agriculture, environmental management, and energy production. ...

However, it's important to ensure the equipment's capacity aligns with the expected demand, as purchasing oversized equipment without sufficient feedstock can result in inefficient operations and increased operating costs. 2. Type of Biochar Production Process The method used to produce biochar—whether through pyrolysis, gasification, or another ...

Agriculture faces an increasing challenge in managing waste, especially manure-contaminated biomass litter. This waste is generated in vast quantities and often disposed of through inefficient or environmentally damaging methods. Pyrolysis, a thermal decomposition process conducted in the absence of oxygen, has emerged as a promising solution for converting biomass waste, including ...