Pyrolysis A Guide To Processing Articles & Analysis: This-Year

23 articles found

Oil sludge, a byproduct of the petroleum industry, is a challenging waste material that requires efficient disposal or treatment. One promising method for processing oil sludge is oil sludge pyrolysis, a thermal decomposition process that breaks down complex hydrocarbons into useful products like oil, gas, and solid residues. However, one crucial factor that significantly affects the efficiency ...

In the face of mounting global waste disposal issues and environmental pollution, the need for innovative waste management solutions has never been greater. Among the most promising technologies is pyrolysis, a thermal decomposition process that not only helps manage waste but also contributes to energy recovery and resource conservation. Pyrolysis technology is quickly gaining traction in the ...

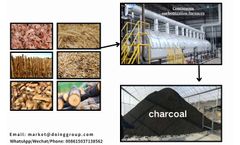

In today's increasingly environmentally conscious world, charcoal maker machines, as an environmentally friendly production equipment, are attracting increasing attention. A charcoal maker machine converts biomass materials into high-quality charcoal through a high-temperature carbonization process. This process not only preserves the energy value of the raw materials but also significantly ...

Catalytic pyrolysis has emerged as a pivotal advancement in thermal conversion technologies, particularly for transforming complex hydrocarbon feedstocks into higher-value liquid fuels. By incorporating specialized catalysts into the pyrolysis process, industrial operators can significantly improve oil yield, enhance product quality, and optimize energy efficiency. This methodology is ...

Starting a small pyrolysis project can be an excellent way to generate profit with a relatively low investment. Pyrolysis, the process of converting organic materials like plastic, rubber, and biomass into valuable products such as fuel, carbon black, and gas, offers substantial financial opportunities for small-scale entrepreneurs. In this blog post, we'll explore how a small pyrolysis machine ...

Tire pyrolysis has garnered significant attention in recent years as an innovative solution to the growing problem of tire waste. By heating tires in the absence of oxygen, pyrolysis converts them into valuable products such as oils, gases, and solid carbon black. Among these byproducts, carbon black plays a critical role in various industries, from rubber production to electronics. However, the ...

The demand for high-quality biochar is surging, thanks to its key role in sustainable agriculture (soil improvement, carbon sequestration), renewable energy and advanced filtration technology. For companies ready to take advantage of this growth opportunity, efficient and sustainable production scale is essential. Biochar is a solid product formed by heating biomass in the absence of oxygen ...

The coconut industry is traditionally known for producing oil, water, milk, and coir, but there’s an often-overlooked byproduct with tremendous untapped value—the coconut shell. Once considered agricultural waste, coconut shells are now gaining recognition as a sustainable raw material for charcoal production, opening up new income streams and adding value across the supply chain. ...

The continuous pyrolysis equipment for plastic, tire, and oil sludge cracking has seen significant advancements in technology that offer improved efficiency, cost savings, and environmental benefits. Below are the three key technological breakthroughs that set this equipment apart: 1. Efficient Oil-Gas Condensation and Anti-Polymerization Technology This technology uses a direct spray mixing ...

In today's world, with the continuous improvement of environmental awareness and the growing demand for energy, biomass energy, as a renewable and clean form of energy, is gradually attracting global attention. With its advanced carbonization equipment, DOING is leading the innovation and development in the field of biomass energy, injecting new vitality into the global energy transformation. ...

The global environmental impact of industrial waste, particularly oil sludge, has become an increasingly pressing issue. The accumulation of oil-contaminated waste in landfills or open environments leads to severe soil contamination, adversely affecting soil quality, biodiversity, and agricultural productivity. However, advancements in pyrolysis technology offer a promising solution to alleviate ...

Pyrolysis reactors play a crucial role in the conversion of waste materials into useful products, such as bio-oil, syngas, and char. Whether you are considering investing in a pyrolysis reactor for industrial purposes or as part of a waste-to-energy project, it's essential to understand the key components of these reactors and the factors to consider when purchasing one. This blog will provide an ...

Biochar production from waste coconut shells has garnered increasing attention as a sustainable business model that not only contributes to environmental conservation but also offers substantial economic benefits. As the demand for renewable resources and waste-to-energy technologies grows, the profitability of biochar production has become an important consideration for businesses and investors ...

The global ocean plastic pollution crisis has reached a critical point. Every year, millions of tons of plastic waste end up in the oceans, threatening marine life, disrupting ecosystems, and creating long-term environmental consequences. Traditional waste management and recycling methods have proven insufficient in addressing the sheer volume of plastic waste, particularly in coastal regions and ...

Catalytic pyrolysis is a modified version of the traditional pyrolysis process. While traditional pyrolysis relies solely on heat to break down organic materials, catalytic pyrolysis introduces a catalyst into the reaction system. The catalyst acts as a facilitator, lowering the activation energy required for chemical reactions to occur. This not only speeds up the pyrolysis process but also ...

The quality of barbecue charcoal is paramount for a superior grilling experience. High-quality charcoal ensures consistent heat, minimal smoke, and extended burn time, which are crucial for grilling food to perfection. Achieving the desired quality requires attention to various factors during both the production and processing stages. From raw material selection to machine efficiency, several ...

Biochar pyrolysis is a thermochemical process that involves heating biomass - materials such as wood, agricultural waste, or dedicated energy crops - in an oxygen - limited environment. As the biomass is heated to temperatures typically ranging from 300°C to 800°C, a series of complex chemical reactions occur. The biomass decomposes, releasing volatile gases like methane, hydrogen, and ...

The growing interest in sustainability and resource efficiency has positioned biochar production as a key element in the circular economy. A biochar machine offers an efficient way to convert organic waste into high-value products that benefit both the environment and the economy. The versatility of biochar, combined with the increasing demand for eco-friendly solutions, makes investing in ...

Biochar production has become an essential part of the sustainable waste management and renewable energy sectors. With its capacity to sequester carbon and improve soil health, biochar holds significant value in environmental and agricultural applications. However, the investment required to acquire biochar production equipment can vary greatly, depending on several critical factors that ...

Agriculture faces an increasing challenge in managing waste, especially manure-contaminated biomass litter. This waste is generated in vast quantities and often disposed of through inefficient or environmentally damaging methods. Pyrolysis, a thermal decomposition process conducted in the absence of oxygen, has emerged as a promising solution for converting biomass waste, including ...