Pyrolysis Reactor Material On Pyrolysis Articles & Analysis: Older

148 articles found

Feeding the Plastic into the pyrolysis vessel: Load the prepared plastic material into the pyrolysis reactor of the machine. Ensure the reactor is sealed properly to maintain the pyrolysis environment. 4. Pyrolysis Process: Initiate the pyrolysis process by ...

The feedstock must be processed to a consistent size for efficient pyrolysis. Typically, the material is shredded or ground to ensure uniformity. ...

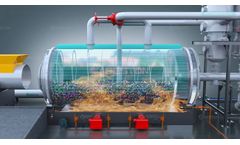

Below is a comprehensive list of the equipment you will need to set up a continuous pyrolysis machine: 1. Pyrolysis Reactor The core component of a continuous pyrolysis machine: Material: Typically made of carbon steel or stainless steel, resistant to high temperatures and corrosive environments. ...

The thermal efficiency of a pyrolysis reactor is a critical factor in determining the overall performance, energy consumption, and economic feasibility of the pyrolysis process. ...

A continuous pyrolysis plant is designed to streamline the conversion of waste materials, such as plastics and tires, into valuable resources like fuel oil, carbon black, and syngas. ...

Sealing is a crucial factor in the overall performance and efficiency of a pyrolysis reactor. The technology behind pyrolysis revolves around the thermal decomposition of materials in the absence of oxygen. ...

When considering investment options for pyrolysis technology, opting for small-scale pyrolysis equipment can be a practical choice, especially if your business processes a limited amount of organic materials. ...

By converting waste materials such as plastics, tires, and biomass into valuable by-products, mini pyrolysis plants offer a sustainable solution to waste management while generating potential revenue streams. ...

Contaminants are removed to improve the efficiency of the pyrolysis process. Heating: The prepared plastic waste is subjected to high temperatures, usually between 300°C and 900°C, in a pyrolysis reactor. ...

This article outlines the types of raw materials suitable for pyrolysis and describes the general process flow of a waste pyrolysis machine. 1. Types of Raw Materials for Pyrolysis (1)Waste Rubber Tires: Pyrolysis can handle various types of waste rubber tires, including steel wire tires, nylon ...

A pyrolysis reactor is a sophisticated piece of equipment used to thermally decompose organic materials in an oxygen-free environment, yielding valuable products such as bio-oil, syngas, and biochar. Proper maintenance of a pyrolysis reactor is critical to ensure its efficient operation, longevity, and safety. ...

In our modern world, waste management has become a pressing global challenge, particularly with the proliferation of non-biodegradable materials like tires and plastics. Continuous pyrolysis equipment, a cutting-edge technology, offers a sustainable solution by converting waste materials into valuable resources such as fuel, chemicals, and raw ...

This method offers a sustainable alternative to straw burning, transforming waste into a valuable resource. The Pyrolysis Process The pyrolysis of straw involves several steps: Feedstock Collection and Preparation: Straw is collected from fields and may be dried to reduce moisture content, ensuring efficient pyrolysis. Pyrolysis ...

Biochar, a form of charcoal produced through the pyrolysis of organic materials such as agricultural waste, has garnered significant attention for its multifaceted advantages. ...

Cooling System: Cools down the charcoal and other materials post-pyrolysis, preparing them for further processing or packaging. ...

The efficiency of the equipment hinges on various factors, including the design of the pyrolysis reactor, the quality of feedstock, and the operating parameters employed during the pyrolysis process. ...

Before delving into the purchase process, it's essential to grasp the fundamentals of plastic pyrolysis equipment. This specialized machinery is designed to convert plastic waste into valuable products such as liquid fuel, gas, and char through a thermochemical process known as pyrolysis. ...

Through controlled heating, biomass undergoes a series of chemical reactions, yielding valuable products like biochar, bio-oil, and syngas.The Biomass Pyrolysis Process: Unraveling the Mechanisms At the core of biomass pyrolysis lies the pyrolysis reactor, a sophisticated apparatus designed to subject the feedstock to high ...

At the heart of every plastic pyrolysis reactor lies a labyrinth of pathways where raw plastic materials embark on a journey of transformation. ...

Often known as the fully-automatic pyrolysis plant, continuous pyrolysis plants use automated screw feeders that feed raw materials directly into a reactor. ...