Refine by

Syngas Articles & Analysis

127 articles found

This integration allows facilities to process post-consumer plastics into market-ready fuels with reduced viscosity, lower sulfur content, and improved combustion properties. Syngas generated during the process can be recycled to heat the reactor, further reducing external fuel demand. ...

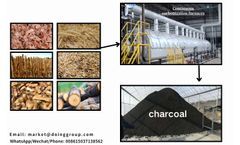

In contrast, modern DOING charcoal machines feature closed-loop systems that recycle syngas for heating, reducing fuel consumption by 40%. Integrated emission control devices (e.g., cyclone separators, spray towers) filter harmful gases, ensuring compliance with global standards. By converting biomass waste into charcoal, these machines also promote circular economies: - Use ...

Energy recovery systems capture syngas generated during pyrolysis, using it as auxiliary fuel to reduce external energy dependency. ...

Byproduct utilization In addition to biochar, pyrolysis also produces syngas and wood vinegar. The combustible gas and liquid products produced can be recycled to reduce overall production costs. ...

Integrating these systems can significantly improve profit margins by reusing generated syngas as process fuel and reducing fuel procurement costs. Site Infrastructure and Utility Requirements Site selection must consider logistics, utilities, and environmental compliance. ...

Heat exchangers and regenerative burners are used to capture and reuse thermal energy from exhaust gases. In some configurations, the syngas generated within the pyrolysis reactor is fed back into the system as a primary heating source, reducing external fuel dependency and improving net energy balance. ...

This zonal heating strategy reduces the formation of tars and waxes while ensuring complete conversion of plastics, rubber, or biomass into oil, syngas, and carbon residue. Moreover, the integration of indirect heating systems—where heat is transferred through reactor walls rather than direct flame contact—minimizes hot spots and material degradation. ...

These facilities, designed to convert organic materials into valuable byproducts like bio-oil, syngas, and biochar, are poised to play a crucial role in shaping the future of renewable energy and waste recycling. ...

A palm shell charcoal machine that operates on a continuous basis further enhances carbon efficiency. By utilizing the syngas generated during pyrolysis as a heat source, it achieves thermal self-sufficiency and lowers reliance on fossil fuels. ...

Gas Cleaning and Treatment System: The pyrolysis process generates gases such as syngas, which may contain harmful impurities. The gas cleaning and treatment system removes tar and other contaminants to ensure that the produced gas is clean and usable as an energy source. ...

A new dawn for carbon utilisation in petrochemicals Imagine a world where the very emissions once considered a burden have become the foundation for cleaner, more efficient fuels. The petrochemical industry is on the brink of achieving such a transformation. The landscape is shifting away from decades-old traditional processes that, while profitable, have contributed significantly to global ...

BySpecac

Gas Recovery and Utilization: One of the important by-products of pyrolysis is syngas, which can be captured and used to fuel the pyrolysis process itself, thus improving energy efficiency. Using syngas for the heating process ensures a continuous, cost-effective operation, minimizing reliance on external energy sources. ...

Energy Generation: The pyrolysis process does not only produce biochar; it also generates by-products such as syngas and bio-oil. These can be harnessed to provide renewable energy. Syngas can be used to power the biochar machine itself, reducing operational costs, while excess energy can be sold to the grid, adding another revenue stream. ...

Introduction Syngas, or synthesis gas, is a vital component in various industrial processes, serving as a fuel source and a raw material for chemical synthesis. It is primarily used in power generation, chemical production, and fuel manufacturing. Accurate measurement of syngas is critical to ensuring efficiency, safety, and compliance with industry standards. ...

The resulting product is stable, resistant to decomposition, and has the potential to sequester carbon for hundreds to thousands of years when applied to soil. Pyrolysis also generates syngas and bio-oil, which can be utilized as renewable energy sources, further reducing reliance on fossil fuels. ...

These include biochar, bio-oil, and syngas, all of which offer numerous advantages over conventional waste disposal methods. ...

Biomass pyrolysis is a thermal decomposition process that converts organic materials—such as agricultural residues, wood chips, or even waste plastics—into valuable biofuels like biochar, syngas, and bio-oil. This process occurs in the absence of oxygen and at high temperatures, allowing for the breakdown of complex organic matter into simpler compounds. ...

For example, high lignin content may lead to a more aromatic, heavier bio-oil, while biomass rich in cellulose tends to produce lighter bio-oil with a higher proportion of aldehydes and alcohols. Syngas Composition: Biomass with higher lignin content produces more syngas, particularly carbon monoxide and methane, which are valuable for energy production. ...

The main components of syngas include carbon monoxide (CO), hydrogen (H₂), carbon dioxide (CO₂), and methane (CH₄), among other trace gases. ...

The byproducts of the process, such as tar and syngas, can also be harnessed for industrial applications, further enhancing resource efficiency. ...