- Home

- Companies

- Beston Group Co., Ltd.

- Articles

- Pyrolysis Plant Output: Fuel Oil, ...

Pyrolysis Plant Output: Fuel Oil, Carbon Black, and Gas Utilization

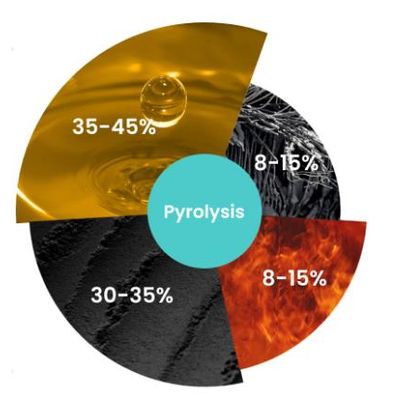

A waste tyre pyrolysis plant converts discarded rubber materials into valuable secondary resources through thermochemical decomposition. Operating under an oxygen-limited environment, this process separates complex hydrocarbon chains into fuel oil, carbon black, and combustible gas. Each output possesses distinct physicochemical characteristics and serves a specific role in industrial energy recovery and material production.

Fuel Oil Recovery and Applications

The primary output of a waste tyre pyrolysis plant is pyrolytic oil, constituting nearly 35–45% of the total yield. This dark, viscous liquid is composed of aromatic hydrocarbons, olefins, and paraffins, closely resembling conventional diesel in calorific value. Its energy content typically ranges from 42 to 44 MJ/kg, making it suitable for direct combustion in industrial furnaces, boilers, and cement kilns.

To expand its application range, the oil can undergo distillation and desulfurization. The refined product—known as pyrolysis diesel—meets higher-grade fuel standards and can be used in heavy machinery or power generators. When integrated into hybrid fuel systems, it offsets fossil fuel consumption and supports low-carbon energy initiatives. Additionally, the recovered oil serves as a feedstock for petrochemical synthesis, facilitating the production of solvents and lubricants in downstream sectors.

Carbon Black Production and Reintegration

Carbon black accounts for approximately 30–35% of the total solid residue derived from the pyrolysis process. This fine, amorphous carbon material exhibits a high surface area and reinforcing properties similar to commercial-grade carbon black. After magnetic separation to remove metallic impurities, it can be upgraded through grinding, pelletizing, and pyrolytic activation.

Industrial applications of recovered carbon black include its use as a filler in rubber compounding, pigment in ink and paint manufacturing, and additive in construction materials. In the case of enhanced processing, its surface modification increases conductivity, making it suitable for use in batteries and conductive polymers. Reutilizing this solid fraction contributes to circular material flow and reduces dependency on virgin petrochemical sources.

Gas Utilization and Energy Feedback

The non-condensable gas generated in a waste tyre pyrolysis plant represents an immediate energy resource for sustaining the process itself. This gas, containing hydrogen, methane, and light hydrocarbons, possesses a calorific value between 18 and 22 MJ/m³. Rather than being vented, it is redirected into the reactor’s heating system through a closed-loop gas recycling line.

This self-sustaining operation reduces the need for external energy inputs and enhances thermal efficiency. In large-scale installations, surplus gas can be purified and compressed for secondary energy recovery, such as electricity generation through gas engines or turbines. The integration of advanced gas purification and heat recovery systems also ensures compliance with environmental regulations, minimizing emissions and thermal loss.

Optimizing Output Utilization

The combined utilization of oil, carbon black, and gas exemplifies the operational efficiency of modern pyrolysis technology. By achieving comprehensive resource recovery, the waste tyre pyrolysis plant transforms environmental liabilities into industrial assets. Through continuous refinement of separation, upgrading, and recycling technologies, this process contributes to both waste reduction and sustainable energy production—advancing a closed-loop model for resource management in the circular economy.