Bertsch Energy GmbH & Co KG products

Sausage Production

BERTSCH - Frozen Meat Cutter

If deep-frozen blocks of meat are to be processed by cutters or mincers, then frozen meat cutters are required to cut the blocks into suitable sizes. The temperature of the frozen blocks can range from –5°C to –25°C. Two technologies have proven successful here and we include them both in our product range. The frozen meat cutter as a guillotine or roller cutter. All of these units feature a solid, robust and, above all safe, construction, with maximum cutting capacity.

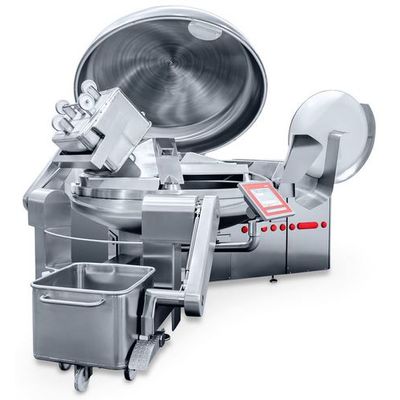

BERTSCH - Proven Cutter Technology

The proven cutter technology is the result of many years of practical experience and continuous improvements. The innovative AC drive technology is the basis for all versions of the technology, combined with extremely solid construction. This means that cutters are suitable both for small as well as large amounts of processing, while at the same time having minimal maintenance costs and low energy consumption. Both fresh meat as well as pre-cut frozen meat can thus be perfectly processed and can also produce rind emulsions.

BERTSCHlaska - Emulsifiers

The emulsifiers (175 – 225 mm perforated disc diameter), also called NanoCutters, were developed for the production of the finest pre-cooked and cooked sausages. By using different perforated discs, the fineness of the sausage meat can be set exactly. This enables the highest quality both when very finely cut as well aswhen coarsely grained. The emulsifiers has user-friendly controls such as a swivelling touchscreen. All of the drive parts are within the machine housing and are ideally protected from soiling. In case of a faulty product, the machine will automatically switch itself off to protect the cutter insert.