- Home

- Companies

- BioGasol ApS

- Products

BioGasol ApS products

Technology

Carbofrac - Biomass Fractionation Technology

The Carbofrac continuous fractionation reactor enables extraction of the sugars contained in a biomass feedstock and is the centrepiece of BioGasol’s technology platform.

FirstSugar - Extraction of Sugars without Enzymes

BioGasol’s Carbofrac system enables unparalleled extraction of hemicellulosic sugars from a number of different types of biomass without the use of enzymes. This offers a unique opportunity to integrate the Carbofrac® system with well-established biomass value chains to enable the production of hemicellulosic sugars as a valuable co-product to the main biomass output (e.g. wood pellets production).

Products - Carbofrac Pretreatment

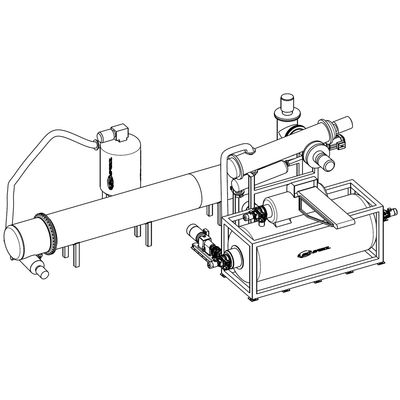

BioGasol Carbofrac - Model 10 (<100kg/h) - Biomass Sugar Extraction System

Designed for pilot testing, process- and feedstock-optimisation, small sample production and R&D applications. Can accommodate both acidic and alkali processes as well as be adapted to multiple step processing. Several units in operation since 2010, also at the BioGasol pilot facility in Denmark.

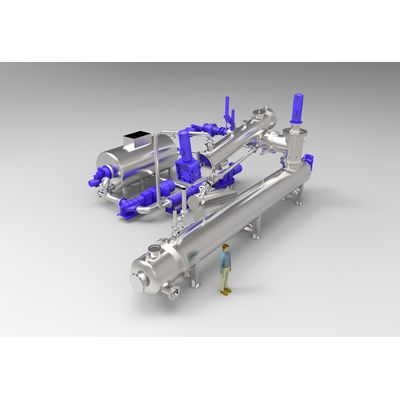

BioGasol Carbofrac - Model 400 (4 tons/h) - Small Commercial Biomass Sugar Extraction System

Fully automated system for production of lignocellulosic sugars from up to four tons of biomass (dry) per hour. Can easily be adapted to feedstock change and a range of process conditions, making it suitable for most biochemical conversion processes. Small foot-print and modular design makes it possible to ship the system in 20’ or 40’ containers.

BioGasol Carbofrac - Model 1200 (12 tons/h) - Large Commercial Biomass Sugar Extraction System

Based on the same design solutions and principles as the smaller units, one single high yielding sugar extraction system is capable of processing up to 12 tons of biomass pr. hour, which translates to 2-3 units for a 60-80 MLPY (million liter per year) 2G bioethanol plant.

Products

Pentocrobe - Biomass Sugar Extraction System

Since 2006 BioGasol has worked regularly with fermentation technology at various scale together with sister company Estibio. The two companies have worked extensively to optimise sugar quality and yields using a unique fermentation process, capable of fermenting all sugar types simultaneously. Estibio’s best-in-class technology platform integrates pentose/hexose co-fermentation process with its patented Pentocrobe microorganisms providing rapid, efficient high yield bioethanol production. The platform is based on very high temperature processing (VHTP) and enables continuous fermentation of both starchy and ligno-cellulosic biomass. BioGasol has access to the Pentocrobe® technology which can be deployed according to the specific project requirements.

BioGasol - Biochemical Processing System

Utilising both the Carbofrac sugar extraction and the Pentocrobe® fermentation platform, BioGasol has demonstrated proof of various process concepts at two different pilot plants: the first (Maxifuel) operated from 2006 to 2008, and the second advanced pilot since 2010 (MaxiCo / MaxiSplit) is still in operation at the BioGasol facilities. Process steps carried out in the BioGasol pilot plants have included biomass conditioning, pretreatment, solid-liquid separations, enzymatic hydrolysis, (C5, C6 and co-) fermentations, distillation and even biogas production. Experimental data from these processes have provided valuable input for scaling-up and evolving the core technologies. However, BioGasols technology can be implemented in many other process concepts for various downstream applications, why BioGasol does not favour or promote one particular process (the figure on this page only provided as an example).