Canadian Hydro Components Ltd. (CHC) products

CHC - Axial Flow Kaplan and Propeller Turbines

CHC supplies more Axial Flow Kaplan and Propeller turbines than any other type of equipment in its product line. These units are built for durability and high efficiency and offer one of the most competitive cost-profitability ratios in the industry. Axial Flow Kaplan turbines feature adjustable wicket gates and turbine blades, to optimize efficiency across a wide range of heads and flows. They are optimal for low head hydro sites (5-35 meters) which experience variable flows throughout the year. Axial Flow Propeller turbines have fixed position turbine blades but allow for wicket gate adjustment and are suited to hydro sites which have little variance in head and flow conditions. In multi-unit plants, Axial Flow Propeller turbines are often installed in combination with Axial Flow Kaplan units for maximum control and flexibility in plant operation.

CHC - Francis Turbines

Francis turbines have been around for 170 years, and have more installations than any other type of turbine in the world today. Numerous designs offering variations in runner height, crown and band diameters, number of buckets, etc make Francis turbines a versatile option for a wide range of hydro projects with heads as low as 12 meters to as high as 600 meters.

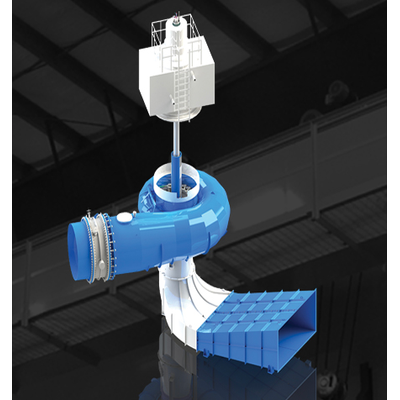

CHC - Conventional Kaplan Turbines

Specifically suited to medium head hydro sites, CHC manufactures a range of conventional Kaplan turbines ranging in size from 500 mm to 3200 mm. Conventional Kaplan turbines feature adjustable turbine blades and wicket gates and are designed to optimize efficiency across a wide range of heads and flows. These turbines are arranged vertically and with a scroll shaped inlet. Flow enters tangentially through vertical guide vanes and wicket gates, spirals vertically through the rotor and exits through a draft tube to recover kinetic energy.

CHC - Replacement Runners

CHC can provide as kind and upgraded replacement runners and turbine components that will often outperform the original equipment. Our engineering team can design and retrofit an improved performance runner within the constraints of an existing powerhouse and ancillary equipment. CHC adopts a system solution for its upgrades: where required, parts are digitized, 3-D models are created, patterns and castings developed and related parts upgraded to provide a proper system solution that will allow the plant owner to maximize the performance of the unit.