- Home

- Companies

- Conifer Systems

- Products

Conifer Systems products

Conifer Systems - Carbon Adsorbers

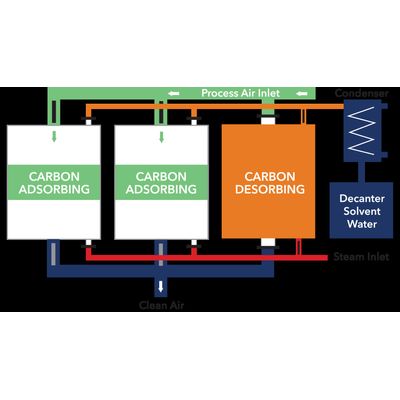

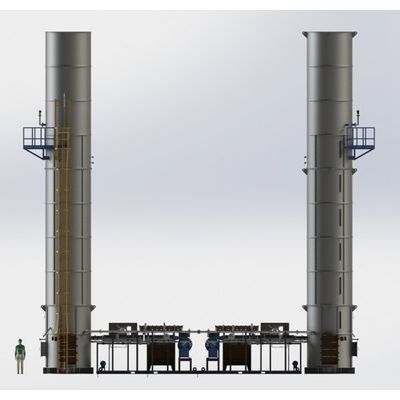

Some industrial applications or compounds require other types of pollution control equipment or additional solutions to create a complete system to neutralize certain chemical bonds or pollutants. Carbon adsorbers can be used on their own, or in addition to other pollution control abatement.

Conifer Systems - Enclosed Flare

Thermal Oxidizers use thermal destruction to abate Volatile Organic Compounds (VOCs). The chemical process raises the process air stream temperature to a point where the chemical bonds are broken. The VOCs in the process air stream are converted to combinations of carbon dioxide, water vapor, and heat by the high temperature of the combustion chamber. For gas streams with low levels of oxygen, dilution with additional air may be required to ensure that enough oxygen is present for complete oxidation of the pollutants. Additionally, more air may be added during periods of high VOC loading to protect from overheating of the internal system components. However, this excess heat does have the benefit of reducing demand on the burner.Air Pollution Control Equipment - Thermal Oxidizers

GCES - Thermal Oxidizers - Afterburners - Direct Fired Thermal Oxidizers

What Is a Direct Fired Thermal Oxidizer, and How Does It Work? A Direct Fired Thermal Oxidizer (DFTO), also known as an Afterburner, or Direct Flame Thermal Oxidizer, destroys Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs), that are created through chemical processes found in industrial exhaust streams. The DFTO destroys these emissions through the process of combustion. The chemical process of thermal oxidation is quite simple; the exhaust stream temperature is raised to between 1,250 to 1,800°F, a temperature at which the chemical bonds that hold the molecules together, are broken.

Other

GCES - Industrial Ovens & Furnaces

GCES designs and manufactures industrial ovens and furnaces tailored to your specific application within a variety of industries. Combining a collaborative approach with our engineering and manufacturing experience, each oven is custom designed to match your unique needs. Considerations include the degree of automation required by your process, temperature control accuracy, safety, material handling, life cycle cost tradeoffs (CAPEX vs OPEX), and other variables that make for a successful industrial oven project.