CS Combustion Solutions GmbH products

Burner

CS - Model SWB - Swirl Burner

The concept of the CS - SWB burner has been proven hundreds of times and the burner has been developed and optimised over decades.

CS - Model SWP - Swirl Pressure Burner

Originally, the SWP burner was developed in order to be able to offer an optimised body design for pressure applications. The simple shape of the burner case, composed of mainly cylindrical and conical shapes, allows the construction of a cost-effective and material-optimised burner for pressure applications.

CS - Model HT - High Temperature Burner

Designed specifically for operation with preheated combustion air, this burner series can have combustion air temperatures above 350°C up to 600°C. The air box of this burner is lined with fireproof concrete to prevent overheating - and above all to prevent unacceptable expansion - of the burner body.

CS - Model RKB - Rotary Kiln Burner

This burner represents the latest development of our standard burners and was specially designed for use on rotary kilns and post-combustion chambers.

Combustors for Thermal Oxidation

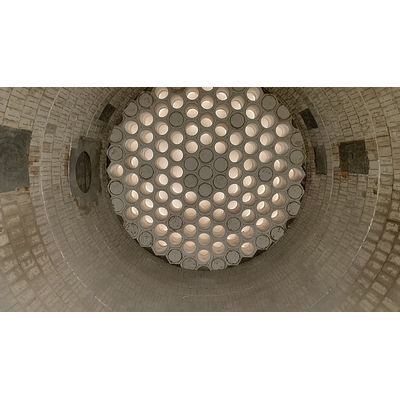

CS - Combustion Chamber

CS Combustion Solutions offers an optimized design of combustion chambers for each application. For each application, each combustor is tailor-made designed, calculated and manufactured to meet the specific challenges and technical characteristics. For sulphuric acid production, SO2 production or waste acid regeneration, combustion chambers with high steel shell temperatures up to 400°C are used during operation. Many years of experience and expertise our CS experts are able to apply in every detail to avoid condensation at various points as well as corrosion and corrosion pitting.

CS - Hot Gas Generators

CS Combustion Solutions builds hot gas generators based on many years of experience and further development. The hot gas generators are used where products have to be dried or plant components such as catalysts have to be heated up and brought to temperature.

Injection Systems - Ultrasonic Nozzles

CS - Model OXIJET/OXISPRAY - Ultrasonic Nozzle with Oxygen

In order to survive economically in a competitive market, plant operators are increasingly faced with the challenge of achieving higher output rates with existing combustion systems. The situation is made more difficult by special low-calorific by-products that oxidise the combustion air through the use of additional booster fuels. Increased flue gas volumes reduce the residence and burnout times or increase the pressure loss of the flue gas. The operator also struggles with poor part-load performance associated with poorly mixed gases and CO strings resulting from the combustion of residues of increasingly variable quality. Conventional air burners do not have the extreme flexibility necessary to solve these problems. CS has worked with customers and partners to develop solutions that can deal with these difficult conditions.

CS - Model OXIJET - Burner

This burner works with oxygen instead of air. After commissioning with a support fuel such as natural gas or heating oil, this burner works with almost any combustible fuel. This process can be retrofitted without having to install a new burner block in the existing combustion chamber. With the special PreCOMB muffle system, it is possible to run additional fuel vapours.

Valve Rack

CS - Valve Rack

Our in-house EI&C department will gladly take over the technical planning and design of the required instrumentation for your burner system. CS supplies everything from loose fittings to fully piped, frame-mounted fuel control stations. We use products of the highest standards from our valve and measurement technology partners, or use manufacturers specified by the customer. Design and manufacturing are carried out in compliance with the most common norms and standards in this field worldwide. On request, we also supply our stations including complete burner control systems.