- Home

- Companies

- DP CleanTech

- Products

DP CleanTech products

Combustion Technology

EcoMulti - Biomass Boiler

The DP EcoMulti biomass boiler is a mainstay product in DP CleanTech’s portfolio and is designed specifically to address 2 significant challenges that are commonly faced by power plant operators in many regions – optimizing output from poor quality fuels; and emissions management. Fuel types vary widely across regions; and in many countries, it is difficult to sustain a consistent fuel type and quality. With DP technology, multi-fuel capabilities are well developed and the range of fuels considered suitable for combustion is extensive. High moisture or poor quality fuels accelerate corrosion and reduce the life cycle of equipment. Such fuel types demand specialist combustion knowledge and the EcoMulti boiler has been designed to optimize combustion; withstand the corrosive effects of such fuels, and to handle multiple fuel types.

MaxMulti - Biomass Boiler

The DP MaxMulti is the most flexible and high performing biomass boiler in DP CleanTech’s portfolio. Using High Pressure High Temperature technology originally developed in Europe, the DP Maxmulti has been further refined and patented to deliver tailored, multiple fuel biomass boilers that are the highest performing solutions available in the market.

MaxSolo - Boiler

The DP MaxSolo is a core product in DP Cleantech’s portfolio, consisting of a specialized, single-fuel ‘high pressure high temperature’ biomass boiler. Whether it is a ‘soft’ fuel such as wheat straw, or a ‘hard’ fuel such as wood, all components of the MaxSolo are specifically designed to maximize the performance from a chosen fuel.

MaxMulti - Model Plus - Anti-Corrosion Biomass Boiler

Multifuel flexibility in biomass boiler combustion is a basic requirement for biomass power plants in China, given the variable nature of the fuel supply for most power plants. 10 years of experience in China have clearly shown that this variability and the quality of fuels most commonly used are the main causes of high levels of boiler corrosion. The most significant impact of fuel-induced corrosion is on fouling, reduction of combustion efficiency and superheater degradation. The results are to be found in lower levels of efficiency, higher maintenance costs and shorter life cycle of the equipment

DP CleanTech - Specialist Boilers

DP Specialist boilers are customized products which are specifically designed to combust complex or difficult fuels. The ‘high pressure high temperature’ boiler technology is manufactured with the most appropriate materials and supplementary systems to cater for the most difficult fuels. Whether it is municipal waste or the lignin byproduct from 2G ethanol production, DP Specialist boilers are specifically designed to reach or even exceed the required performance levels from a chosen fuel, or from several, given fuel types.

Gasification Technology

Energos - Waste to Energy Gasification Technology

DP’s gasification solution is a commercially proven European waste to energy gasification technology from Energos. This extensively proven technology is suitable for converting all types of non-recyclable commercial and household waste to energy; and has the added benefit of very low emissions. The patented technology is highly flexible and modular, to meet smaller scale needs for distributed power and can be expanded accordingly to optimise fuel processing capacity and energy production.

Standalone Technoligies

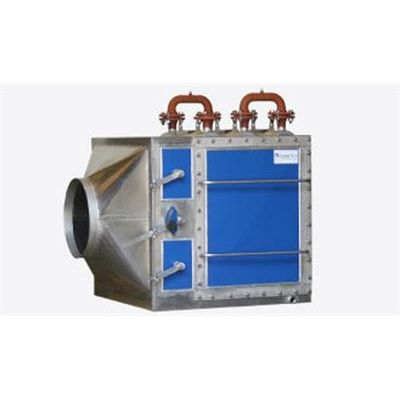

Boiler Technologies

DP’s Water Cooled Vibrating Grate (WCVG) is a grate technology and component integral to the DP boiler product range. Developed specifically for the high efficiency firing of biomass at the lowest possible emission rates, the Water Cooled Vibrating Grate is a highly reliable and proven technology which has been refined and optimized by DP through many years of operational experience and pioneering modifications. It has been fully integrated with DP’s patented combustion system to produce the most efficient High Pressure, High Temperature straw-fired boiler technology in the world.

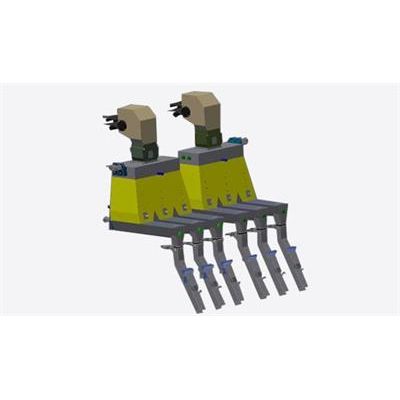

Fuel Handling Equipment

Different fuels have different handling and feeding characteristics. To improve efficiency and reduce the common problems of blockage and unburned carbon, DP has made modifications which reduces the height and simplifies the arrangement of the fuel feeding system. The introduction of a variable capacity system increases flexibility; and operating cost benefits include a longer lifecycle for reclaimer blades; and a simpler control system to manage and reduce power consumption.