- Home

- Companies

- Flame Spray SpA

- Products

Flame Spray SpA products

Technology - Diffusion

Flame Spray - Diffusion Coating

Flame Spray offers a full range of diffusive coatings including Platinum Aluminide (Pt-Al) and Si-modified Aluminide (Si-modified Aluminide). Protect your engine components, turbines, fuel cells and more with our high quality coatings. Our Pt-Al coatings provide exceptional oxidation protection at high combustion temperatures up to 1,100°C. For more economical options, our Si-modified aluminides are effective at lower temperatures. If flexibility is what you are looking for, our standard aluminides are widely used and reliable! If you are looking for a versatile and reliable solution, our standard aluminides are widely used for a variety of applications, ensuring resistance and protection in very critical environments.

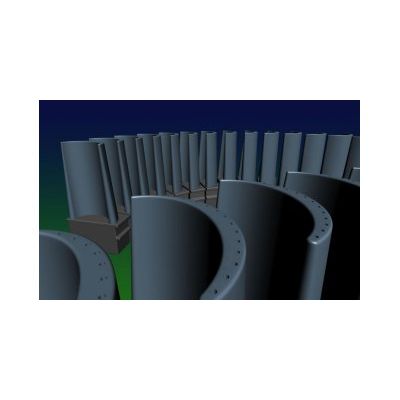

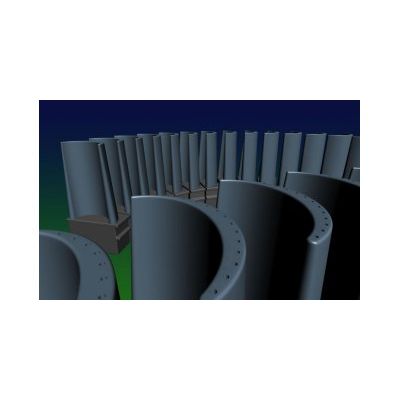

Gas Turbines

Droplet Erosion

Gas turbines are generally considered the most cost effective and relatively environment-friendly large scale power generation technology, but their capacity as well as their thermal efficiency degrades under high ambient temperature conditions. Fogging Systems provide the most cost effective technique to recover this lost gas turbine capacity through adiabatic cooling of the gas turbine inlet air by the spraying of atomized water in the axial compressors. Nevertheless the water injection can cause droplet erosion phenomena on the first stages of blades of the compressor. That degradation can be avoided by applying an erosion/corrosion-resistant coating like our FlameSeal 834 System.

Caboflam - Model H 500 Series - High-Pressure Combustion Equipment

Caboflam H trademark identifies Flame Spray`s technological processes for carbide coatings in metallic matrix through high-pressure combustion equipment (HP/HVOF). These types of coatings exhibit excellent bond strength, higher micro hardness and density than those produced with traditional detonation equipment.

Alloy - Model H 500 Series - High-Pressure Combustion Equipment

Flame Spray has developed a specific process, Alloy H 500 series, for metallic coatings through high-pressure combustion equipment (HP/HVOF). A peculiarity of the Alloy H 500 series processes consists in the possibility to obtain very dense coatings with excellent bond strength, better oxidation and corrosion and wear resistance than those produced with traditional detonation equipment.

Alucote - Model HT - Oxidation Coating

Aluminizing has proven to be a cost effective way of increasing the resistance of metals to oxidation and corrosion at high temperature. Although for some markets it is a mature technology, new application methods and new formulations continuously extend its application field. Ni, Co, Fe, Ti base alloys can successfully be treated with modern aluminizing processes.

Alloy - Model H 900 Series - Oxidation Coating

Flame Spray has developed a specific process, Alloy H 900 series, for metallic coatings through high-pressure combustion equipment (HP/HVOF). A peculiarity of the Alloy H 900 series processes consists in the possibility to obtain very dense coatings with excellent bond strength, better oxidation and corrosion resistance than those produced with traditional detonation equipment.

Alucote - HT Corrosion

Aluminizing has proven to be a cost effective way of increasing the resistance of metals to oxidation and corrosion at high temperature. Although for some markets it is a mature technology, new application methods and new formulations continuously extend its application field. Ni, Co, Fe, Ti base alloys can successfully be treated with modern aluminizing processes.

Alloy - Model H 900 Series - HT Corrosion

Flame Spray has developed a specific process, Alloy H 900 series, for metallic coatings through high-pressure combustion equipment (HP/HVOF). A peculiarity of the Alloy H 900 series processes consists in the possibility to obtain very dense coatings with excellent bond strength, better oxidation and corrosion resistance than those produced with traditional detonation equipment.

Waste Burners

Severe and High Temperature Corrosion

At metal temperatures higher than 350°C with high chlorine percentage in the fuel gas, catalytic corrosion of carbon/low alloy steel can reach metal wastages of > 2 mm/year.

Oil and Gas

Metal to Metal in valves

Valves in petrochemical applications have to face very severe operating conditions in which corrosion and wear are very critical factors for the service life cycle. Metal to Metal (MtM) valves can guarantee superior protection against such problems.