Forney Corporation products

Burners - Utility Burners

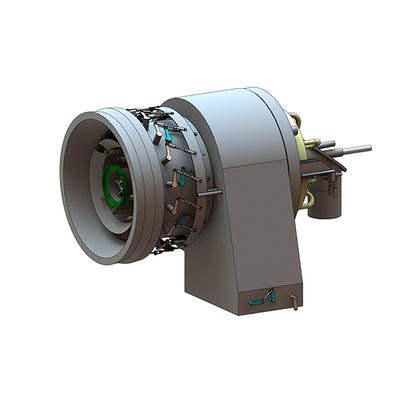

Forney - Model Eagle AIR II - Coal/Gas Burner

Forney in Conjunction with Storm Technologies brings you the Eagle Air II Burner! Need the ability to fire both coal or natural gas so your plant can take advantage of the most cost effective fuel option? Eagle Air II is a Wall-Fired-Boiler Dual-Fuel Burner that gives you that flexibility.

Forney - Parallel Air Flow Burners (PAF)

Forney Parallel Air Flow (PAF) burners are custom engineered for a wide range of heat inputs while providing the flexibility of firing a variety of fuel types.

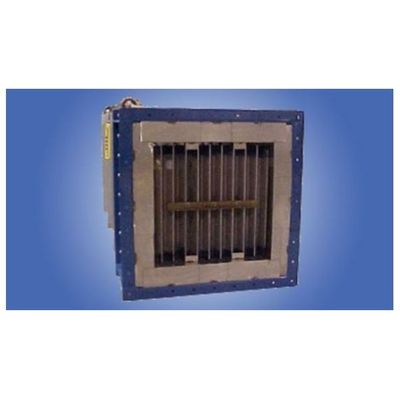

Forney - Model SCR - Reheating Burners

Power plants must meet both stringent NOx reduction regulation and their customers’ needs of varying electricity demands by reducing their boiler’s steam production. Reducing boiler load causes lower flue gas temperatures reducing the operating abilities of NOx control equipment such as selective catalytic reduction (SCR) reactors. Forney Corporation utilized its vast combustion experience to develop a line of SCR reheaters to supplement flue gas temperatures. When firing conditions dictate the need for this additional heat, Forney’s SCR reheaters pump heat into the flue gas stream, thereby maintaining a flue gas temperature that ensures maximum SCR efficiency. Forney can design a system for any configuration using one of three solutions, sure to satisfy your installation requirements.

Burners - Duct Burners

adVantage - Duct Burner

adVantage Duct Burners perform in the most challenging conditions. Premium components and patented technology join to perform like no other duct burner.

adVantage - Liquid Fuel Duct Burners

Our Liquid Fuel Duct Burners inject fuel from the side of the duct to keep the fuel cool until it is burned. An “anchoring” baffle ensures the flame spans the duct to provide even heat distribution. Our patented technology ensures excellent mixing of the turbine exhaust gas and fuel, resulting in clean combustion with reduced CO emissions. Our design eliminates performance variations by using a small amount of external combustion air as opposed to burners that rely solely on turbine exhaust gas for their oxidant.

Igniters

MAXFire - Model 100 Series - Gas Igniter System

The MAXFire® 100 Series gas igniter incorporates the “protected primary combustion zone” design in each of the 5 capacities available. The ignition process starts inside the guide tube away from the burner environment resulting in an extremely stable and reliable igniter. Capacities (nominal) range from 1 mmBtu/hr to 50 mmBtu/hr. MAXFire® gas igniters provide the most reliable source of energy for main flame ignition, flame stabilization, and boiler warm-up.